Applied theory of contact interaction of elastic bodies and the creation on its basis of the processes of shaping friction-rolling bearings with rational geometry. Theory of contact interaction of deformable solid bodies with circular boundaries, taking into account mechanical

1. MODERN PROBLEMS OF CONTACT MECHANICS

INTERACTIONS

1.1. Classical hypotheses used in solving contact problems for smooth bodies

1.2. Influence of Creep of Solids on Their Shape Change in the Contact Area

1.3. Estimation of convergence of rough surfaces

1.4. Analysis of the contact interaction of multilayer structures

1.5. Relationship between mechanics and problems of friction and wear

1.6. Features of the use of modeling in tribology 31 CONCLUSIONS ON THE FIRST CHAPTER

2. CONTACT INTERACTION OF SMOOTH CYLINDRICAL BODIES

2.1. Solution of the contact problem for smooth isotropic disk and plate with a cylindrical cavity

2.1.1. General formulas

2.1.2. Derivation of the boundary condition for displacements in the contact area

2.1.3. Integral equation and its solution 42 2.1.3.1. Study of the resulting equation

2.1.3.1.1. Reduction of a singular integro-differential equation to an integral equation with a kernel having a logarithmic singularity

2.1.3.1.2. Estimating the Norm of a Linear Operator

2.1.3.2. Approximate solution of the equation

2.2. Calculation of a fixed connection of smooth cylindrical bodies

2.3. Determination of displacement in a movable connection of cylindrical bodies

2.3.1. Solution of an auxiliary problem for an elastic plane

2.3.2. Solution of an auxiliary problem for an elastic disk

2.3.3. Determination of maximum normal radial displacement

2.4. Comparison of theoretical and experimental data on the study of contact stresses at internal contact of cylinders of close radii

2.5. Modeling of Spatial Contact Interaction of a System of Coaxial Cylinders of Finite Sizes

2.5.1. Formulation of the problem

2.5.2. Solution of auxiliary two-dimensional problems

2.5.3. Solution of the original problem 75 CONCLUSIONS AND MAIN RESULTS OF THE SECOND CHAPTER

3. CONTACT PROBLEMS FOR ROUGH BODIES AND THEIR SOLUTION BY CORRECTING THE CURVATURE OF A DEFORMED SURFACE

3.1. Spatial non-local theory. geometric assumptions

3.2. Relative convergence of two parallel circles determined by roughness deformation

3.3. Method for Analytical Evaluation of the Influence of Roughness Deformation

3.4. Definition of displacements in the area of contact

3.5. Definition of auxiliary coefficients

3.6. Determination of the dimensions of the elliptical contact area

3.7. Equations for determining the contact area close to circular

3.8. Equations for determining the area of contact close to the line

3.9. Approximate determination of the coefficient a in the case of a contact area in the form of a circle or a SW strip

3.10. Peculiarities of averaging pressures and strains in solving the two-dimensional problem of internal contact of rough cylinders with close radii Yu

3.10.1. Derivation of the integro-differential equation and its solution in the case of internal contact of rough cylinders Yu

3.10.2. Definition of auxiliary coefficients ^ ^

3.10.3. Stress fit of rough cylinders ^ ^ CONCLUSIONS AND MAIN RESULTS OF CHAPTER THREE

4. SOLUTION OF CONTACT PROBLEMS OF VISCOELASTICITY FOR SMOOTH BODIES

4.1. Basic provisions

4.2. Compliance principles analysis

4.2.1. Volterra principle

4.2.2. Constant coefficient of transverse expansion under creep deformation

4.3. Approximate solution of the two-dimensional contact problem of linear creep for smooth cylindrical bodies ^^

4.3.1. General case of viscoelasticity operators

4.3.2. Solution for a monotonically increasing contact area

4.3.3. Fixed connection solution

4.3.4. Modeling of contact interaction in the case of uniformly aging isotropic plate

CONCLUSIONS AND MAIN RESULTS OF THE FOURTH CHAPTER

5. SURFACE CREEP

5.1. Features of the contact interaction of bodies with low yield strength

5.2. Construction of a Surface Deformation Model Taking into Account Creep in the Case of an Elliptical Contact Area

5.2.1. geometric assumptions

5.2.2. Surface Creep Model

5.2.3. Determination of average deformations of a rough layer and average pressures

5.2.4. Definition of auxiliary coefficients

5.2.5. Determination of the dimensions of the elliptical contact area

5.2.6. Determining the dimensions of the circular contact area

5.2.7. Determining the width of the contact area as a strip

5.3. Solution of a 2D Contact Problem for Internal Touch of Rough Cylinders with Allowance for Surface Creep

5.3.1. Statement of the problem for cylindrical bodies. Integro- differential equation

5.3.2. Determination of auxiliary coefficients 160 CONCLUSIONS AND MAIN RESULTS OF THE FIFTH CHAPTER

6. MECHANICS OF INTERACTION OF CYLINDRICAL BODIES WITH COVERINGS

6.1. Calculation of effective modules in the theory of composites

6.2. Construction of a self-consistent method for calculating the effective coefficients of inhomogeneous media, taking into account the spread of physical and mechanical properties

6.3. Solution of the contact problem for a disk and a plane with an elastic composite coating on the hole contour

6.3.1. Statement of the problem and basic formulas

6.3.2. Derivation of the boundary condition for displacements in the contact area

6.3.3. Integral equation and its solution

6.4. Solution of the Problem in the Case of an Orthotropic Elastic Coating with Cylindrical Anisotropy

6.5. Determination of the effect of viscoelastic aging coating on the change in contact parameters

6.6. Analysis of the Features of the Contact Interaction of a Multicomponent Coating and the Roughness of a Disc

6.7. Modeling of contact interaction taking into account thin metal coatings

6.7.1. Contact of a plastic-coated ball and a rough half-space

6.7.1.1. Main hypotheses and model of interaction of rigid bodies

6.7.1.2. Approximate solution of the problem

6.7.1.3. Determination of the maximum contact approach

6.7.2. Solution of the contact problem for a rough cylinder and a thin metal coating on the hole contour

6.7.3. Determination of contact stiffness at internal contact of cylinders

CONCLUSIONS AND MAIN RESULTS OF CHAPTER SIX

7. SOLUTION OF MIXED BOUNDARY PROBLEM WITH SURFACE WEAR INCLUDED

OF INTERACTING BODIES

7.1. Features of the solution of the contact problem, taking into account the wear of surfaces

7.2. Statement and solution of the problem in the case of elastic deformation of roughness

7.3. The method of theoretical wear assessment taking into account surface creep

7.4. Method for assessing wear taking into account the influence of the coating

7.5. Concluding remarks on the formulation of plane problems with wear taken into account

CONCLUSIONS AND MAIN RESULTS OF THE SEVENTH CHAPTER

Recommended list of dissertations

On the contact interaction between thin-walled elements and viscoelastic bodies under torsion and axisymmetric deformation, taking into account the aging factor 1984, candidate of physical and mathematical sciences Davtyan, Zaven Azibekovich

Static and dynamic contact interaction of plates and cylindrical shells with rigid bodies 1983, candidate of physical and mathematical sciences Kuznetsov, Sergey Arkadievich

Technological support of the durability of machine parts based on hardening treatment with simultaneous application of anti-friction coatings 2007, doctor of technical sciences Bersudsky, Anatoly Leonidovich

Thermoelastic contact problems for bodies with coatings 2007, candidate of physical and mathematical sciences Gubareva, Elena Alexandrovna

A technique for solving contact problems for bodies of arbitrary shape, taking into account surface roughness by the finite element method 2003, Candidate of Technical Sciences Olshevsky, Alexander Alekseevich

Introduction to the thesis (part of the abstract) on the topic "Theory of contact interaction of deformable solids with circular boundaries, taking into account the mechanical and microgeometric characteristics of surfaces"

The development of technology poses new challenges in the field of research into the performance of machines and their elements. Increasing their reliability and durability is the most important factor determining the growth of competitiveness. In addition, the lengthening of the service life of machinery and equipment, even to a small extent with a high saturation of technology, is tantamount to the commissioning of significant new production capacities.

The state of the art in the theory of machine workflows combined with extensive experimental techniques to determine workloads and high level The development of the applied theory of elasticity, with the available knowledge of the physical and mechanical properties of materials, makes it possible to ensure the overall strength of machine and apparatus parts with a sufficiently large guarantee against breakage under normal service conditions. At the same time, the trend towards a decrease in the weight and size indicators of the latter with a simultaneous increase in their energy saturation makes it necessary to revise the known approaches and assumptions in determining the stress state of parts and require the development of new calculation models, as well as the improvement of experimental research methods. Analysis and classification of failures of mechanical engineering products showed that the main cause of failure under operating conditions is not breakage, but wear and damage to their working surfaces.

Increased wear of parts in the joints in some cases violates the tightness of the working space of the machine, in others - the normal lubrication regime, in the third - leads to a loss of the kinematic accuracy of the mechanism. Wear and damage to surfaces reduces the fatigue strength of parts and can cause their destruction after a certain service life with minor structural and technological concentrators and low rated stresses. Thus, increased wear disrupts the normal interaction of parts in assemblies, can cause significant additional loads and cause accidental damage.

All this attracted a wide range of scientists of various specialties, designers and technologists to the problem of increasing the durability and reliability of machines, which made it possible not only to develop a number of measures to increase the service life of machines and create rational methods for caring for them, but also based on the achievements of physics, chemistry, and metal science to lay the foundations for the doctrine of friction, wear and lubrication in mates.

At present, significant efforts of engineers in our country and abroad are aimed at finding ways to solve the problem of determining the contact stresses of interacting parts, since for the transition from the calculation of the wear of materials to the problems of structural wear resistance, the contact problems of the mechanics of a deformable solid have a decisive role. Solutions of contact problems of elasticity theory for bodies with circular boundaries are of essential importance for engineering practice. They make up theoretical basis calculation of such machine elements as bearings, swivel joints, some types of gears, interference connections.

The most extensive studies have been carried out using analytical methods. It is the presence of fundamental connections between modern complex analysis and potential theory with such a dynamic field as mechanics that determined their rapid development and use in applied research. The use of numerical methods significantly expands the possibilities of analyzing the stress state in the contact area. At the same time, the bulkiness of the mathematical apparatus, the need to use powerful computing tools significantly hinders the use of existing theoretical developments in solving applied problems. Thus, one of the topical directions in the development of mechanics is to obtain explicit approximate solutions to the problems posed, ensuring the simplicity of their numerical implementation and describing the phenomenon under study with sufficient accuracy for practice. However, despite the successes achieved, it is still difficult to obtain satisfactory results taking into account the local design features and microgeometry of the interacting bodies.

It should be noted that the properties of the contact have a significant impact on the wear processes, since, due to the discreteness of the contact, microroughnesses touch only on separate areas that form the actual area. In addition, the protrusions formed during processing are diverse in shape and have a different distribution of heights. Therefore, when modeling the topography of surfaces, it is necessary to introduce parameters characterizing the real surface into the statistical laws of distribution.

All this requires the development of a unified approach to solving contact problems taking into account wear, which most fully takes into account both the geometry of interacting parts, microgeometric and rheological characteristics of surfaces, their wear resistance characteristics, and the possibility of obtaining an approximate solution with the least number of independent parameters.

Connection of work with major scientific programs, topics. The studies were carried out in accordance with the following topics: "To develop a method for calculating contact stresses with elastic contact interaction of cylindrical bodies, not described by the Hertz theory" (Ministry of Education of the Republic of Belarus, 1997, No. GR 19981103); "Influence of microroughnesses of contacting surfaces on the distribution of contact stresses in the interaction of cylindrical bodies with similar radii" (Belarusian Republican Foundation for Fundamental Research, 1996, No. GR 19981496); "To develop a method for predicting the wear of sliding bearings, taking into account the topographic and rheological characteristics of the surfaces of interacting parts, as well as the presence of anti-friction coatings" (Ministry of Education of the Republic of Belarus, 1998, No. GR 1999929); "Modeling the contact interaction of machine parts, taking into account the randomness of the rheological and geometric properties of the surface layer" (Ministry of Education of the Republic of Belarus, 1999 No. GR 20001251)

Purpose and objectives of the study. Development of a unified method for theoretical prediction of the influence of geometric, rheological characteristics of the surface roughness of solids and the presence of coatings on the stress state in the contact area, as well as the establishment on this basis of the patterns of change in contact stiffness and wear resistance of mates using the example of the interaction of bodies with circular boundaries.

To achieve this goal, it is necessary to solve the following problems:

To develop a method for the approximate solution of problems in the theory of elasticity and viscoelasticity on the contact interaction of a cylinder and a cylindrical cavity in a plate using a minimum number of independent parameters.

Develop a non-local model of the contact interaction of bodies, taking into account the microgeometric, rheological characteristics of surfaces, as well as the presence of plastic coatings.

Substantiate an approach that allows correcting the curvature of interacting surfaces due to roughness deformation.

To develop a method for the approximate solution of contact problems for a disk and isotropic, orthotropic with cylindrical anisotropy and viscoelastic aging coatings on a hole in a plate, taking into account their transverse deformability.

Build a model and determine the influence of microgeometric features of the surface of a solid body on the contact interaction with a plastic coating on the counterbody.

To develop a method for solving problems taking into account the wear of cylindrical bodies, the quality of their surfaces, as well as the presence of anti-friction coatings.

The object and subject of the study are non-classical mixed problems of the theory of elasticity and viscoelasticity for bodies with circular boundaries, taking into account the non-locality of the topographic and rheological characteristics of their surfaces and coatings, on the example of which we have developed complex method analysis of changes in the stress state in the contact area depending on the quality indicators of their surfaces.

Hypothesis. When solving the set boundary problems, taking into account the quality of the surface of the bodies, a phenomenological approach is used, according to which the deformation of the roughness is considered as the deformation of the intermediate layer.

Problems with time-varying boundary conditions are considered as quasi-static.

Methodology and methods of the research. When conducting research, the basic equations of mechanics of a deformable solid body, tribology, and functional analysis were used. A method has been developed and substantiated that makes it possible to correct the curvature of loaded surfaces due to deformations of microroughnesses, which greatly simplifies the ongoing analytical transformations and makes it possible to obtain analytical dependences for the size of the contact area and contact stresses, taking into account the indicated parameters without using the assumption of the smallness of the value of the base length for measuring the roughness characteristics relative to the dimensions. contact areas.

When developing a method for theoretical prediction of surface wear, the observed macroscopic phenomena were considered as the result of the manifestation of statistically averaged relationships.

The reliability of the results obtained in the work is confirmed by comparisons of the obtained theoretical solutions and results experimental studies, as well as comparison with the results of some solutions found by other methods.

Scientific novelty and significance of the obtained results. For the first time, using the example of the contact interaction of bodies with circular boundaries, a generalization of studies was carried out and a unified method for complex theoretical prediction of the influence of non-local geometric, rheological characteristics of rough surfaces of interacting bodies and the presence of coatings on the stress state, contact stiffness and wear resistance of interfaces was developed.

The complex of researches carried out made it possible to present in the dissertation a theoretically substantiated method for solving problems of solid mechanics, based on the consistent consideration of macroscopically observed phenomena, as a result of the manifestation of microscopic bonds statistically averaged over a significant area of the contact surface.

As part of solving the problem:

A three-dimensional non-local model of the contact interaction of solid bodies with isotropic surface roughness is proposed.

A method has been developed for determining the influence of the surface characteristics of solids on the stress distribution.

The integro-differential equation obtained in contact problems for cylindrical bodies is investigated, which made it possible to determine the conditions for the existence and uniqueness of its solution, as well as the accuracy of the constructed approximations.

Practical (economic, social) significance of the obtained results. The results of the theoretical study have been brought to methods acceptable for practical use and can be directly applied in the engineering calculations of bearings, sliding bearings, and gears. The use of the proposed solutions will reduce the time of creating new machine-building structures, as well as predict their service characteristics with great accuracy.

Some of the results of the research carried out were implemented at the NLP "Cycloprivod", NPO "Altech".

The main provisions of the dissertation submitted for defense:

Approximate solution of the problem of mechanics of a deformed solid on the contact interaction of a smooth cylinder and a cylindrical cavity in a plate, describing the phenomenon under study with sufficient accuracy using a minimum number of independent parameters.

Solution of non-local boundary value problems of mechanics of a deformable solid body, taking into account the geometric and rheological characteristics of their surfaces, based on a method that makes it possible to correct the curvature of interacting surfaces due to roughness deformation. The absence of an assumption about the smallness of the geometric dimensions of the base lengths of the roughness measurement in comparison with the dimensions of the contact area allows us to proceed to the development of multilevel models of deformation of the surface of solids.

Construction and substantiation of a method for calculating the displacements of the boundary of cylindrical bodies due to the deformation of surface layers. The results obtained make it possible to develop a theoretical approach that determines the contact stiffness of mates, taking into account the joint influence of all the features of the state of the surfaces of real bodies.

Modeling of the viscoelastic interaction between a disk and a cavity in a plate made of aging material, the ease of implementation of the results of which allows them to be used for a wide range of applied problems.

Approximate solution of contact problems for a disk and isotropic, orthotropic with cylindrical anisotropy, as well as viscoelastic aging coatings on a hole in a plate, taking into account their transverse deformability. This makes it possible to evaluate the effect of composite coatings with a low modulus of elasticity on the loading of interfaces.

Construction of a non-local model and determination of the influence of the characteristics of the roughness of the surface of a solid body on the contact interaction with a plastic coating on the counterbody.

Development of a method for solving boundary value problems, taking into account the wear of cylindrical bodies, the quality of their surfaces, as well as the presence of anti-friction coatings. On this basis, a methodology is proposed that focuses mathematical and physical methods in the study of wear resistance, which makes it possible, instead of studying real friction units, to focus on the study of phenomena occurring in the contact area.

Applicant's personal contribution. All results submitted for defense were obtained by the author personally.

Approbation of the results of the dissertation. The results of the research presented in the dissertation were presented at 22 international conferences and congresses, as well as conferences of the CIS and republican countries, among them: "Pontryagin readings - 5" (Voronezh, 1994, Russia), "Mathematical models of physical processes and their properties" ( Taganrog, 1997, Russia), Nordtrib"98 (Ebeltoft, 1998, Denmark), Numerical mathematics and computational mechanics - "NMCM"98" (Miskolc, 1998, Hungary), "Modelling"98" (Praha, 1998, Czech Republic), 6th International Symposium on Creep and Coupled Processes (Bialowieza, 1998, Poland), "Computational methods and production: reality, problems, prospects" (Gomel, 1998, Belarus), "Polymer composites 98" (Gomel, 1998, Belarus), " Mechanika"99" (Kaunas, 1999, Lithuania), II Belarusian Congress on Theoretical and Applied Mechanics

Minsk, 1999, Belarus), Internat. Conf. On Engineering Rheology, ICER"99 (Zielona Gora, 1999, Poland), "Problems of strength of materials and structures in transport" (St. Petersburg, 1999, Russia), International Conference on Multifield Problems (Stuttgart, 1999, Germany).

Publication of results. Based on the materials of the dissertation, 40 printed works were published, among them: 1 monograph, 19 articles in journals and collections, including 15 articles under personal authorship. The total number of pages of published materials is 370.

The structure and scope of the dissertation. The dissertation consists of an introduction, seven chapters, a conclusion, a list of references and an appendix. The total volume of the dissertation is 275 pages, including the volume occupied by illustrations - 14 pages, tables - 1 page. The number of sources used includes 310 items.

Similar theses in the specialty "Mechanics of a deformable solid body", 01.02.04 VAK code

Development and research of the process of smoothing the surface of gas-thermal coatings of textile machine parts in order to increase their performance 1999, candidate of technical sciences Mnatsakanyan, Victoria Umedovna

Numerical simulation of dynamic contact interaction of elastoplastic bodies 2001, candidate of physical and mathematical sciences Sadovskaya, Oksana Viktorovna

Solution of contact problems in the theory of plates and plane non-Hertzian contact problems by the boundary element method 2004, candidate of physical and mathematical sciences Malkin, Sergey Aleksandrovich

Discrete Simulation of the Rigidity of Jointed Surfaces in the Automated Estimation of the Accuracy of Process Equipment 2004, Candidate of Technical Sciences Korzakov, Alexander Anatolyevich

Optimal design of contact pair parts 2001, doctor of technical sciences Hajiyev Vahid Jalal oglu

Dissertation conclusion on the topic "Mechanics of a deformable solid body", Kravchuk, Alexander Stepanovich

CONCLUSION

In the course of the research carried out, a number of static and quasi-static problems of the mechanics of a deformable solid body were posed and solved. This allows us to formulate the following conclusions and indicate the results:

1. Contact stresses and surface quality are one of the main factors determining the durability of machine-building structures, which, combined with a tendency to reduce the weight and size indicators of machines, the use of new technological and structural solutions, leads to the need to revise and refine the approaches and assumptions used in determining the stress state , displacements and wear in mates. On the other hand, the cumbersomeness of the mathematical apparatus, the need to use powerful computing tools significantly hinder the use of existing theoretical developments in solving applied problems and define one of the main directions in the development of mechanics to obtain explicit approximate solutions of the problems posed, ensuring the simplicity of their numerical implementation.

2. An approximate solution of the problem of mechanics of a deformable solid on the contact interaction of a cylinder and a cylindrical cavity in a plate with a minimum number of independent parameters is constructed, which describes the phenomenon under study with sufficient accuracy.

3. For the first time non-local boundary value problems of the theory of elasticity are solved taking into account the geometric and rheological characteristics of roughness on the basis of a method that allows correcting the curvature of interacting surfaces. The absence of an assumption about the smallness of the geometric dimensions of the base lengths of the roughness measurement in comparison with the dimensions of the contact area makes it possible to correctly formulate and solve problems of the interaction of solid bodies, taking into account the microgeometry of their surfaces at relatively small contact sizes, and also to proceed to the creation of multilevel models of roughness deformation.

4. A method is proposed for calculating the largest contact displacements in the interaction of cylindrical bodies. The results obtained made it possible to construct a theoretical approach that determines the contact stiffness of mates, taking into account the microgeometric and mechanical features of the surfaces of real bodies.

5. Modeling of the viscoelastic interaction between the disk and the cavity in a plate made of aging material was carried out, the simplicity of the implementation of the results of which allows them to be used for a wide range of applied problems.

6. Contact problems are solved for a disk and isotropic, orthotropic with cylindrical anisotropy, and viscoelastic aging coatings on a hole in a plate, taking into account their transverse deformability. This makes it possible to evaluate the effect of composite antifriction coatings with a low modulus of elasticity.

7. A model is built and the influence of the microgeometry of the surface of one of the interacting bodies and the presence of plastic coatings on the surface of the counterbody is determined. This makes it possible to emphasize the leading influence of the surface characteristics of real composite bodies in the formation of the contact area and contact stresses.

8. A general method has been developed for solving cylindrical bodies, the quality of their anti-friction coatings. boundary value problems, taking into account the wear of surfaces, as well as the presence

List of references for dissertation research Doctor of Physical and Mathematical Sciences Kravchuk, Alexander Stepanovich, 2004

1. Ainbinder S.B., Tyunina E.L. Introduction to the theory of polymer friction. Riga, 1978. - 223 p.

2. Alexandrov V.M., Mkhitaryan S.M. Contact problems for bodies with thin coatings and interlayers. M.: Nauka, 1983. - 488 p.

3. Aleksandrov V.M., Romalis B.L. Contact problems in mechanical engineering. -M.: Mashinostroenie, 1986. 176 p.

4. Alekseev V.M., Tumanova O.O. Alekseeva A.V. Characteristics of the contact of a single unevenness under conditions of elastic-plastic deformation Friction and wear. - 1995. - T.16, N 6. - S. 1070-1078.

5. Alekseev N.M. Metal coatings of sliding bearings. M: Mashinostroenie, 1973. - 76 p.

6. Alekhin V.P. Physics of strength and plasticity of surface layers of materials. M.: Nauka, 1983. - 280 p.

7. Alies M.I., Lipanov A.M. Creation of mathematical models and methods for calculating hydrogeodynamics and deformation of polymeric materials. // Problems of mechan. and materials scientist. Issue. 1/ RAS UrO. Institute of Applied fur. -Izhevsk, 1994. S. 4-24.

8. Amosov I.S., Skragan V.A. Accuracy, vibration and surface finish in turning. M.: Mashgiz, 1953. - 150 p.

9. Andreikiv A.E., Chernets M.V. Estimation of contact interaction of rubbing machine parts. Kyiv: Naukova Dumka, 1991. - 160 p.

10. Antonevich A.B., Radyno Ya.V. Functional analysis and integral equations. Mn .: Publishing house "University", 1984. - 351 p.

11. P. Arutyunyan N.Kh., Zevin A.A. Calculation of building structures taking into account creep. M.: Stroyizdat, 1988. - 256 p.

12. Harutyunyan N.Kh. Kolmanovsky V.B. Theory of creep of inhomogeneous bodies. -M.: Nauka, 1983.- 336 p.

13. Atopov V.I. Stiffness control of contact systems. M: Mashinostroenie, 1994. - 144 p.

14. Buckley D. Surface phenomena during adhesion and frictional interaction. M.: Mashinostroenie, 1986. - 360 p.

15. Bakhvalov N.S. Panasenko G.P. Averaging processes in periodic problems. Mathematical problems of the mechanics of composite materials. -M.: Nauka, 1984. 352 p.

16. Bakhvalov N.S., Eglist M.E. Effective modules of thin-walled structures // Bulletin of Moscow State University, Ser. 1. Mathematics, mechanics. 1997. - No. 6. -S. 50-53.

17. Belokon A.V., Vorovich I.I. Contact problems of the linear theory of viscoelasticity without taking into account the forces of friction and cohesion. Izv. Academy of Sciences of the USSR. MTT. -1973,-№6.-S. 63-74.

18. Belousov V.Ya. Durability of machine parts with composite materials. Lvov: High school, 1984. - 180 p.

19. Berestnev O.V., Kravchuk A.S., Yankevich N.S. Development of a method for calculating the contact strength of the lantern gearing of planetary lantern gears / / Progressive gears: Sat. dokl., Izhevsk, June 28-30, 1993 / OR. Izhevsk, 1993. - S. 123-128.

20. Berestnev O.V., Kravchuk A.S., Yankevich N.S. Contact strength of highly loaded parts of planetary pinion gears // Gear transmissions-95: Proc. of Intern. Congress, Sofia, 26-28 September, 1995. P. 6870.

21. Berestnev O.V., Kravchuk A.S., Yankevich H.C. Contact interaction of cylindrical bodies // Doklady ANB. 1995. - T. 39, No. 2. - S. 106-108.

22. Bland D. Theory of linear viscoelasticity. M.: Mir, 1965. - 200 p.

23. Bobkov V.V., Krylov V.I., Monastyrny P.I. Computational methods. In 2 volumes. Volume I. M.: Nauka, 1976. - 304 p.

24. Bolotin B.B. Novichkov Yu.N. Mechanics of multilayer structures. M.: Mashinostroenie, 1980. - 375 p.

25. Bondarev E.A., Budugaeva V.A., Gusev E.JI. Synthesis of layered shells from a finite set of viscoelastic materials // Izv. RAS, MTT. 1998. - No. 3. -S. 5-11.

26. Bronstein I.N., Semendyaev A.S. Handbook of mathematics for engineers and students of higher educational institutions. M.: Nauka, 1981. - 718 p.

27. Bryzgalin G.I. Creep tests of glass-reinforced plastic plates // Journal of Applied Mathematics and Technical Physics. 1965. - No. 1. - S. 136-138.

28. Bulgakov I.I. Remarks on the hereditary theory of metal creep // Journal of Applied Mathematics and Technical Physics. 1965. - No. 1. - S. 131-133.

29. Storm A.I. Influence of the nature of the fiber on the friction and wear of carbon fiber // On the nature of the friction of solids: Proceedings. report International Symposium, Gomel June 8-10, 1999 / IMMS NASB. Gomel, 1999. - S. 44-45.

30. Bushuev V.V. Fundamentals of machine tool design. M.: Stankin, 1992. - 520 p.

31. Vainshtein V.E., Troyanovskaya G.I. Dry lubricants and self-lubricating materials. - M.: Mashinostroenie, 1968. 179 p.

32. Wang Fo Py G.A. Theory of reinforced materials. Kyiv: Nauk, dum., 1971.-230 p.

33. Vasiliev A.A. Continuum Modeling of Deformation of a Two-Row Finite Discrete System with Boundary Effects // Bulletin of Moscow State University, Ser. 1 mate., fur, - 1996. No. 5. - S. 66-68.

34. Wittenberg Yu.R. Surface roughness and methods for its evaluation. M.: Shipbuilding, 1971.- 98 p.

35. Vityaz V.A., Ivashko B.C., Ilyushenko A.F. Theory and practice of applying protective coatings. Mn.: Belarusskaya Navuka, 1998. - 583 p.

36. Vlasov V.M., Nechaev JI.M. Performance of high-strength thermal diffusion coatings in friction units of machines. Tula: Priokskoye Prince. publishing house, 1994. - 238 p.

37. Volkov S.D., Stavrov V.P. Statistical mechanics of composite materials. Minsk: Publishing house of BSU im. IN AND. Lenin, 1978. - 208 p.

38. Volterra V. Theory of functionals, integral and integro-differential equations. M.: Nauka, 1982. - 302 p.

39. Questions of analysis and approximation: Sat. scientific papers / Academy of Sciences of the Ukrainian SSR Institute of Mathematics; Editorial staff: Korneichuk N.P. (responsible ed.) etc. Kyiv: Institute of Mathematics of the Academy of Sciences of the Ukrainian SSR, 1989, - 122 p.

40. Voronin V.V., Tsetsokho V.A. Numerical solution of an integral equation of the first kind with a logarithmic singularity by the method of interpolation and collocation // Zhurnal Vychisl. mat. and mat. physics. 1981. - v. 21, No. 1. - S. 40-53.

41. Galin L.A. Contact problems of the theory of elasticity. Moscow: Gostekhizdat, 1953.264 p.

42. Galin L.A. Contact problems of the theory of elasticity and viscoelasticity. M.: Nauka, 1980, - 304 p.

43. Garkunov D.N. Tribotechnics. M.: Mashinostroenie, 1985. - 424 p.

44. Hartman E.V., Mironovich L.L. Wear-resistant protective polymer coatings // Friction and wear. -1996, - v. 17, No. 5. S. 682-684.

45. Gafner S.L., Dobychin M.N. On the calculation of the contact angle at internal contact of cylindrical bodies, the radii of which are almost equal // Mashinovedenie. 1973. - No. 2. - S. 69-73.

46. Gakhov F.D. Boundary tasks. M.: Nauka, 1977. - 639 p.

47. Gorshkov A.G., Tarlakovsky D.V. Dynamic contact problems with moving boundaries. -M.: Science: Fizmatlit, 1995.-351 p.

48. Goryacheva I.G. Calculation of contact characteristics taking into account the parameters of macro- and microgeometry of surfaces // Friction and wear. 1999. - Vol. 20, No. 3. - S. 239-248.

49. I. G. Goryacheva, A. P. Goryachev, and F. Sadegi, “Contacting Elastic Bodies with Thin Viscoelastic Coatings under Rolling or Sliding Friction,” Prikl. math. and fur. vol. 59, no. 4. - S. 634-641.

50. Goryacheva I.G., Dobychin N.M. Contact problems in tribology. M.: Mashinostroenie, 1988. - 256 p.

51. Goryacheva I.G., Makhovskaya Yu.Yu. Adhesion during the interaction of elastic bodies // On the nature of friction of solid bodies: Proceedings. report International Symposium, Gomel June 8-10, 1999 / IMMS NASB. Gomel, 1999. - S. 31-32.

52. Goryacheva I.G., Torskaya E.V. Stress state of a two-layer elastic base with incomplete adhesion of layers // Friction and wear. 1998. -t. 19, No. 3, -S. 289-296.

53. Mushroom V.V. Solution of tribological problems numerical methods. M.: Nauka, 1982. - 112 p.

54. Grigolyuk E.I., Tolkachev V.M. Contact problems, theory of plates and shells. M.: Mashinostroenie, 1980. - 416 p.

55. Grigolyuk E.I., Filyptinsky L.A. Perforated plates and shells. M.: Nauka, 1970. - 556 p.

56. Grigolyuk E.I., Filyptinsky L.A. Periodic piecewise homogeneous structures. M.: Nauka, 1992. - 288 p.

57. Gromov V.G. On the mathematical content of the Volterra principle in the boundary value problem of viscoelasticity // Prikl. math. and fur. 1971. - v. 36., No. 5, - S. 869-878.

58. Gusev E.L. Mathematical methods for the synthesis of layered structures. -Novosibirsk: Nauka, 1993. 262 p.

59. Danilyuk I.I. Irregular boundary value problems on the plane. M.: Nauka, 1975. - 295s.

60. Demkin N.B. Contacting rough surfaces. M.: Nauka, 1970.- 227 p.

61. Demkin N.B. Theory of contact of real surfaces and tribology // Friction and wear. 1995. - T. 16, No. 6. - S. 1003-1025.

62. Demkin N.B., Izmailov V.V., Kurova M.S. Determination of the statistical characteristics of a rough surface based on profilograms // Rigidity of machine-building structures. Bryansk: NTO Mashprom, 1976.-S. 17-21.

63. Demkin N.B., Korotkoe M.A. Estimation of the topographic characteristics of a rough surface using profilograms // Mechanics and Physics of Contact Interaction. Kalinin: KGU, 1976. - p. 3-6.

64. Demkin N.B., Ryzhov E.V. Surface quality and contact of machine parts. -M., 1981, - 244 p.

65. Johnson K. Mechanics of contact interaction. M: Mir, 1989. 510 p.

66. Dzene I.Ya. Change in Poisson's ratio at full cycle one-dimensional creep //Mekhan. polymers. 1968. - No. 2. - S. 227-231.

67. Dinarov O.Yu., Nikolsky V.N. Determination of relations for a viscoelastic medium with microrotations // Prikl. math. and fur. 1997. - v. 61, no. 6.-S. 1023-1030.

68. Dmitrieva T.V. Sirovatka L.A. Composite coatings for antifriction purposes obtained using tribotechnics // Sat. tr. intl. scientific and technical conf. "Polymer composites 98" Gomel September 29-30, 1998 / IMMS ANB. Gomel, 1998. - S. 302-304.

69. Dobychin M.N., Gafner C.JL Influence of friction on the contact parameters of the shaft-sleeve // Problems of friction and wear. Kyiv: Technique. - 1976, No. 3, -S. 30-36.

70. Dotsenko V.A. Wear of solids. M.: TsINTIKhimneftemash, 1990. -192 p.

71. Drozdov Yu.N., Kovalenko E.V. Theoretical study of the resource of plain bearings with insert // Friction and wear. 1998. - T. 19, No. 5. - S. 565-570.

72. Drozdov Yu.N., Naumova N.M., Ushakov B.N. Contact stresses in swivel joints with slide bearings // Problems of mechanical engineering and reliability of machines. 1997. - No. 3. - S. 52-57.

73. Dunin-Barkovsky I.V. The main directions of research of surface quality in mechanical engineering and instrumentation // Vestnik mashinostroeniya. -1971. No. 4. - S.49-50.

74. Dyachenko P.E., Yakobson M.O. Surface quality in metal cutting. M.: Mashgiz, 1951.- 210 p.

75. Efimov A.B., Smirnov V.G. Asymptotically exact solution of the contact problem for a thin multilayer coating // Izv. RAN. MTT. -1996. No. 2. -S.101-123.

76. Zharin A.JI. Method of contact potential difference and its application in tribology. Mn.: Bestprint, 1996. - 240 p.

77. Zharin A.L., Shipitsa H.A. Methods for studying the surface of metals by registering changes in the work function of an electron // On the nature of friction of solid bodies: Proceedings. report International Symposium, Gomel June 8-10, 1999 /IMMSANB. Gomel, 1999. - S. 77-78.

78. Zhdanov G.S., Khunjua A.G. Lectures on solid state physics. M: Publishing House of Moscow State University. 1988.-231 p.

79. Zhdanov G.S. Solid State Physics.- M: Publishing House of Moscow State University, 1961.-501 p.

80. Zhemochkin N.B. Theory of elasticity. M., Gosstroyizdat, 1957. - 255 p.

81. Zaitsev V.I., Shchavelin V.M. A method for solving contact problems taking into account the real properties of the roughness of the surfaces of interacting bodies // МТТ. -1989. No. 1. - S.88-94.

82. Zakharenko Yu.A., Proplat A.A., Plyashkevich V.Yu. Analytical solution of the equations of the linear theory of viscoelasticity. Application to TVEL nuclear reactors. Moscow, 1994. - 34p. - (Preprint / Russian science Center"Kurchatov Institute"; IAE-5757 / 4).

83. Zenguil E. Surface Physics. M.: Mir, 1990. - 536 p.

84. Zolotorevsky B.C. Mechanical properties of metals. M.: Metallurgy, 1983. -352s.

85. Ilyushin I.I. Approximation method of structures according to the linear theory of thermo-visco-elasticity // Mekhan. polymers. 1968.-№2.-S. 210-221.

86. Inyutin I.S. Electrostrain measurements in plastic parts. Tashkent: State. Published by UzSSR, 1972. 58 p.

87. Karasik I.I. Tribological test methods in the national standards of the countries of the world. M.: Center "Science and Technology". - 327 p.

88. Kalandiya A.I. On contact problems in the theory of elasticity, Prikl. math. and fur. 1957. - Vol. 21, No. 3. - S. 389-398.

89. Kalandiya A.I. Mathematical methods of two-dimensional theory of elasticity // M.: Nauka, 1973. 304 p.

90. Kalandiya A.I. On one direct method for solving the wing equation and its application in the theory of elasticity // Mathematical collection. 1957. - v.42, No. 2. - S.249-272.

91. Kaminsky A.A., Ruschitsky Ya.Ya. On the applicability of the Volterra principle in the study of crack motion in hereditarily elastic media, Prikl. fur. 1969. - v. 5, no. 4. - S. 102-108.

92. Kanaun S.K. Self-consistent field method in the problem of effective properties of an elastic composite // Prikl. fur. and those. physical 1975. - No. 4. - S. 194-200.

93. Kanaun S.K., Levin V.M. Effective field method. Petrozavodsk: Petrozavodsk state. Univ., 1993. - 600 p.

94. Kachanov L.M. Creep theory. M: Fizmatgiz, 1960. - 455 p.

95. Kobzev A.V. Construction of a non-local model of a multi-modulus viscoelastic body and numerical solution of a three-dimensional model of convection in the bowels of the Earth. Vladivostok. - Khabarovsk.: UAFO FEB RAN, 1994. - 38 p.

96. Kovalenko E.V. Math modeling elastic bodies bounded by cylindrical surfaces // Friction and wear. 1995. - T. 16, No. 4. - S. 667-678.

97. Kovalenko E.V., Zelentsov V.B. Asymptotic Methods in Nonstationary Dynamic Contact Problems // Prikl. fur. and those. physical 1997. - V. 38, No. 1. - S.111-119.

98. Kovpak V.I. Prediction of long-term performance of metallic materials under creep conditions. Kyiv: Academy of Sciences of the Ukrainian SSR, Institute of Strength Problems, 1990. - 36 p.

99. Koltunov M.A. Creep and relaxation. M.: Higher school, 1976. - 277 p.

100. Kolubaev A.V., Fadin V.V., Panin V.E. Friction and wear of composite materials with a multilevel damping structure // Friction and wear. 1997. - Vol. 18, No. 6. - S. 790-797.

101. Kombalov B.C. Effect of rough solids on friction and wear. M.: Nauka, 1974. - 112 p.

102. Kombalov B.C. Development of the theory and methods for increasing the wear resistance of friction surfaces of machine parts // Problems of mechanical engineering and reliability of machines. 1998. - No. 6. - S. 35-42.

103. Composite materials. M: Nauka, 1981. - 304 p.

104. Kravchuk A.S., Chigarev A.V. Mechanics of contact interaction of bodies with circular boundaries. Minsk: Technoprint, 2000 - 198 p.

105. Kravchuk A.S. On the stress fit of parts with cylindrical surfaces / / New technologies in mechanical engineering and computer technology: Proceedings of X scientific and technical. Conf., Brest 1998 / BPI Brest, 1998. - S. 181184.

106. Kravchuk A.S. Determination of wear of rough surfaces in the mating of cylindrical sliding bearings // Materials, technologies, tools. 1999. - V. 4, No. 2. - p. 52-57.

107. Kravchuk A.S. Contact problem for composite cylindrical bodies // Mathematical modeling of a deformable solid body: Sat. articles / Ed. O.J.I. Swede. Minsk: NTK HAH Belarus, 1999. - S. 112120.

108. Kravchuk A.S. Contact interaction of cylindrical bodies taking into account the parameters of their surface roughness // Applied Mechanics and Technical Physics. 1999. - v. 40, No. 6. - S. 139-144.

109. Kravchuk A.S. Non-local contact of a rough curvilinear body and a body with a plastic coating // Teoriya i praktika mashinostroeniya. No. 1, 2003 - p. 23 - 28.

110. Kravchuk A.S. Influence of galvanic coatings on the strength of stressed fits of cylindrical bodies // Mechanics "99: materials of the II Belarusian Congress on Theoretical and Applied Mechanics, Minsk, June 28-30, 1999 / IMMS NASB. Gomel, 1999. - 87 p.

111. Kravchuk A.S. Nonlocal contact of rough bodies over an elliptical region // Izv. RAN. MTT. 2005 (in press).

112. Kragelsky I.V. Friction and wear. M.: Mashinostroenie, 1968. - 480 p.

113. Kragelsky I.V., Dobychin M.N., Kombalov B.C. Fundamentals of calculations for friction and wear. M: Mashinostroenie, 1977. - 526 p.

114. Kuzmenko A.G. Contact problems taking into account wear for cylindrical sliding bearings // Friction and wear. -1981. T. 2, No. 3. - S. 502-511.

115. Kunin I.A. Theory of elastic media with microstructure. Nonlocal theory of elasticity, - M.: Nauka, 1975. 416 p.

116. Lankov A.A. Compression of rough bodies with spherical contact surfaces // Friction and wear. 1995. - T. 16, No. 5. - S.858-867.

117. Levina Z.M., Reshetov D.N. Contact stiffness of machines. M: Mashinostroenie, 1971. - 264 p.

118. Lomakin V.A. Plane Problem of the Theory of Elasticity of Microheterogeneous Bodies // Inzh. magazine, MTT. 1966. - No. 3. - S. 72-77.

119. Lomakin V.A. Theory of elasticity of inhomogeneous bodies. -M.: Publishing House of Moscow State University, 1976. 368 p.

120. Lomakin V.A. Statistical problems of solid mechanics. M.: Nauka, 1970. - 140 p.

121. Lurie S.A., Yousefi Shahram. On the determination of the effective characteristics of inhomogeneous materials // Mekh. composite mater, and designs. 1997. - Vol. 3, No. 4. - S. 76-92.

122. Lyubarsky I.M., Palatnik L.S. Metal physics of friction. M.: Metallurgy, 1976. - 176 p.

123. Malinin H.H. Creep in metal processing. M. Mashinostroenie, 1986.-216 p.

124. Malinin H.H. Calculations for creep of elements of machine-building structures. M.: Mashinostroenie, 1981. - 221 p.

125. Manevich L.I., Pavlenko A.V. Asymptotic method in micromechanics of composite materials. Kyiv: Vyscha school, 1991. -131 p.

126. Martynenko M.D., Romanchik B.C. On the solution of integral equations of the contact problem of the theory of elasticity for rough bodies // Prikl. fur. and mat. 1977. - V. 41, No. 2. - S. 338-343.

127. Marchenko V.A., Khruslov E.Ya. Boundary Value Problems in Regions with a Fine-Grained Boundary. Kyiv: Nauk. Dumka, 1974. - 280 p.

128. Matvienko V.P., Yurova N.A. Identification of Effective Elastic Constant Composite Shells Based on Statistical and Dynamic Experiments, Izv. RAN. MTT. 1998. - No. 3. - S. 12-20.

129. Makharsky E.I., Gorokhov V.A. Fundamentals of mechanical engineering technology. -Mn.: Higher. school, 1997. 423 p.

130. Interlayer Effects in Composite Materials, Ed. N. Pegano -M.: Mir, 1993, 346 p.

131. Mechanics of composite materials and structural elements. In 3 volumes. T. 1. Mechanics of materials / Guz A.N., Khoroshun L.P., Vanin G.A. etc. - Kiev: Nauk, Dumka, 1982. 368 p.

132. Mechanical properties of metals and alloys / Tikhonov L.V., Kononenko V.A., Prokopenko G.I., Rafalovsky V.A. Kyiv, 1986. - 568 p.

133. Milashinovi Dragan D. Reoloshko-dynamic analog. // Fur. Mater, and design: 36. glad. Scientific stingy, April 17-19, 1995, Beograd, 1996, p. 103110.

134. Milov A.B. On the calculation of the contact stiffness of cylindrical joints // Problems of strength. 1973. - No. 1. - S. 70-72.

135. Mozharovsky B.B. Methods for solving contact problems for layered orthotropic bodies // Mechanics 95: Sat. abstract report Belarusian Congress on Theoretical and Applied Mechanics, Minsk February 6-11, 1995 / BSPA-Gomel, 1995. - S. 167-168.

136. Mozharovsky V.V., Smotrenko I.V. Mathematical modeling of the interaction of a cylindrical indenter with a fibrous composite material // Friction and wear. 1996. - Vol. 17, No. 6. - S. 738742.

137. Mozharovsky V.V., Starzhinsky V.E. Applied mechanics of layered bodies from composites: Plane contact problems. Minsk: Science and technology, 1988. -271 p.

138. Morozov E.M., Zernin M.V. Contact problems of fracture mechanics. -M: Mashinostroenie, 1999. 543 p.

139. Morozov E.M., Kolesnikov Yu.V. Mechanics of contact destruction. M: Nauka, 1989, 219s.

140. Muskhelishvili N.I. Some basic problems of the mathematical theory of elasticity. M.: Nauka, 1966. - 708 p.

141. Muskhelishvili N.I. Singular integral equations. M.: Nauka, 1968. -511s.

142. Narodetsky M.Z. On a contact problem // DAN SSSR. 1943. - T. 41, No. 6. - S. 244-247.

143. Nemish Yu.N. Spatial boundary value problems in the mechanics of piecewise homogeneous bodies with non-canonical interfaces // Prikl. fur. -1996.-T. 32, No. 10.- S. 3-38.

144. Nikishin B.C., Shapiro G.S. Problems of the theory of elasticity for multilayer media. M.: Nauka, 1973. - 132 p.

145. Nikishin B.C., Kitoroage T.V. Plane contact problems of the theory of elasticity with one-way constraints for multilayer media. Calc. Center of the Russian Academy of Sciences: Communications on applied mathematics, 1994. - 43 p.

146. New substances and products from them as objects of inventions / Blinnikov

147. V.I., Dzhermanyan V.Yu., Erofeeva S.B. etc. M.: Metallurgy, 1991. - 262 p.

148. Pavlov V.G. Development of tribology at the Institute of Mechanical Engineering of the Russian Academy of Sciences // Problems of mechanical engineering and reliability of machines. 1998. - No. 5. - S. 104-112.

149. Panasyuk V.V. Contact problem for a circular hole // Problems of mechanical engineering and strength in mechanical engineering. 1954. - v. 3, No. 2. - S. 59-74.

150. Panasyuk V.V., Teplyi M.I. Change the tension in the cylinders at the ixth inner contact! DAN URSR, Series A. - 1971. - No. 6. - S. 549553.

151. Pankov A.A. Generalized self-consistency method: modeling and calculation of effective elastic properties of composites with random hybrid structures // Mekh. composite mater, and construct. 1997. - vol. 3, no. 4.1. C. 56-65.

152. Pankov A.A. Analysis of effective elastic properties of composites with random structures by a generalized self-consistency method. Izv. RAN. MTT. 1997. - No. 3. - S. 68-76.

153. Pankov A.A. Averaging of thermal conduction processes in composites with random structures from composite or hollow inclusions general method self-consistency // Mech. composite mater, and construct. 1998. - V. 4, No. 4. - S. 42-50.

154. Parton V.Z., Perlin P.I. Methods of mathematical theory of elasticity. -M.: Nauka, 1981.-688 p.

155. Pelekh B.L., Maksimuk A.V., Korovaichuk I.M. Contact problems for layered structural elements. Kyiv: Nauk. Doom., 1988. - 280 p.

156. Petrokovets M.I. Development of Discrete Contact Models as Applied to Metal-Polymer Friction Units: Abstract of the thesis. diss. . doc. those. Sciences: 05.02.04/IMMS. Gomel, 1993. - 31 p.

157. Petrokovets M.I. Some problems of mechanics in tribology // Mechanics 95: Sat. abstract report Belarusian Congress on Theoretical and Applied Mechanics Minsk, February 6-11, 1995 / BSPA. - Gomel, 1995. -S. 179-180.

158. Pinchuk V.G. Analysis of the dislocation structure of the surface layer of metals during friction and the development of methods for increasing their wear resistance: Abstract of the thesis. diss. . doc. those. Sciences: 05.02.04 / IMMS. Gomel, 1994. - 37 p.

159. Pobedrya B.E. Principles of Computational Mechanics of Composites // Mekh. composite mater. 1996. - T. 32, No. 6. - S. 729-746.

160. Pobedrya B.E. Mechanics of composite materials. M .: Publishing house of sinks, un-ta, 1984, - 336 p.

161. Pogodaev L.I., Golubaev N.F. Approaches and criteria in assessing the durability and wear resistance of materials // Problems of mechanical engineering and reliability of machines. 1996. - No. 3. - S. 44-61.

162. Pogodaev L.I., Chulkin S.G. Modeling of wear processes of materials and machine parts based on the structural-energy approach // Problems of mechanical engineering and reliability of machines. 1998. - No. 5. - S. 94-103.

163. Polyakov A.A., Ruzanov F.I. Friction based on self-organization. M.: Nauka, 1992, - 135 p.

164. Popov G.Ya., Savchuk V.V. Contact problem of the theory of elasticity in the presence of a circular contact area, taking into account the surface structure of contacting bodies. Izv. Academy of Sciences of the USSR. MTT. 1971. - No. 3. - S. 80-87.

165. Prager V., Hodge F. Theory of ideally plastic bodies. Moscow: Nauka, 1951. - 398 rubles.

166. Prokopovich I.E. On the solution of a plane contact problem in the theory of creep, Prikl. math. and fur. 1956. - Vol. 20, issue. 6. - S. 680-687.

167. Application of creep theories in metal forming / Pozdeev A.A., Tarnovsky V.I., Eremeev V.I., Baakashvili V.S. M., Metallurgy, 1973. - 192 p.

168. Prusov I.A. Thermoelastic anisotropic plates. Mn.: From BSU, 1978 - 200 p.

169. Rabinovich A.S. On the solution of contact problems for rough bodies // Izv. Academy of Sciences of the USSR. MTT. 1979. - No. 1. - S. 52-57.

170. Rabotnov Yu.N. Selected works. Problems of Mechanics of a Deformable Solid Body. M.: Nauka, 1991. - 196 p.

171. Rabotnov Yu.N. Mechanics of a Deformed Solid Body. M.: Nauka, 1979, 712 p.

172. Rabotnov Yu.N. Elements of hereditary mechanics of solids. M.: Nauka, 1977. - 284 p.

173. Rabotnov Yu.N. Calculation of machine parts for creep // Izv. USSR Academy of Sciences, OTN. 1948. - No. 6. - S. 789-800.

174. Rabotnov Yu.N. Creep theory // Mechanics in the USSR for 50 years, vol. 3. -M.: Nauka, 1972. S. 119-154.

175. Strength calculations in mechanical engineering. In 3 volumes. Volume II: Some Problems of Applied Theory of Elasticity. Calculations beyond elasticity. Creep calculations / Ponomarev S.D., Biderman B.JL, Likharev et al. Moscow: Mashgiz, 1958. 974 p.

176. Rzhanitsyn A.R. Creep theory. M: Stroyizdat, 1968.-418s.

177. Rosenberg V.M. Creep of metals. Moscow: Metallurgy, 1967. - 276 p.

178. Romalis N.B. Tamuzh V.P. Destruction of structurally inhomogeneous bodies. - Riga: Zinatne, 1989. 224 p.

179. Ryzhov E.V. Contact stiffness of machine parts. M.: Mashinostroenie, 1966 .- 195 p.

180. Ryzhov E.V. Nauchnye osnovy tekhnologicheskogo upravleniya kachestva surfacing detal' pri machinirovaniya [Scientific bases of technological control over the surface quality of parts during mechanical processing]. Friction and wear. 1997. -V.18, No. 3. - S. 293-301.

181. Rudzit Ya.A. Microgeometry and contact interaction of surfaces. Riga: Zinatne, 1975. - 214 p.

182. Ruschitsky Ya.Ya. About one contact task plane theory viscoelasticity //Prikl. fur. 1967. - Vol. 3, issue. 12. - S. 55-63.

183. Savin G.N., Wang Fo Py G.A. Stress Distribution in a Plate of Fibrous Materials, Prikl. fur. 1966. - Vol. 2, issue. 5. - S. 5-11.

184. Savin G.N., Ruschitsky Ya.Ya. On the applicability of the Volterra principle // Mechanics of Deformable Solids and Structures. M.: Mashinostroenie, 1975. - p. 431-436.

185. Savin G.N., Urazgildyaev K.U. Influence of creep and ctla of a material on the stress state near holes in a plate, Prikl. fur. 1970. - Vol. 6, issue. 1, - S. 51-56.

186. Sargsyan B.C. Contact problems for half-planes and strips with elastic overlays. Yerevan: Publishing House of Yerevan University, 1983. - 260 p.

187. Sviridenok A.I. Tribology development trend in countries former USSR(1990-1997) // Friction and wear. 1998, Vol. 19, No. 1. - S. 5-16.

188. Sviridenok A.I., Chizhik S.A., Petrokovets M.I. Mechanics of Discrete Friction Contact. Mn.: Navuka i tekhshka, 1990. - 272 p.

189. Serfonov V.N. The use of creep and relaxation kernels in the form of a sum of exponentials in solving some problems of linear viscoelasticity by the operator method // Tr. Map. state. those. university 1996. - V. 120, No. 1-4. - FROM.

190. Sirenko G.A. Anti-friction carboplasties. Kyiv: Technique, 1985.109.125.195s.

191. Skorynin Yu.V. Diagnostics and management of service characteristics of tribosystems taking into account hereditary phenomena: Operational and information materials / IND MASH AS BSSR. Minsk, 1985. - 70 p.

192. Skripnyak V.A., Pyarederin A.B. Modeling of the process of plastic deformation of metallic materials taking into account the evolution of dislocation substructures // Izv. universities. Physics. 1996. - 39, No. 1. - S. 106-110.

193. Skudra A.M., Bulavas F.Ya. Structural theory of reinforced plastics. Riga: Zinatne, 1978. - 192 p.

194. Soldatenkov I.A. Solving the contact problem for a strip-half-plane composition in the presence of wear with a changing contact area. Izv. RAS, MTT. 1998. - №> 2. - p. 78-88.

195. Sosnovsky JI.A., Makhutov N.A., Shurinov V.A. The main regularities of wear-fatigue damage. Gomel: BelIIZhT, 1993. -53 p.

196. Resistance to deformation and plasticity of steel at high temperatures / Tarnovsky I.Ya., Pozdeev A.A., Baakashvili V.S. etc. - Tbilisi: Sabchota Sakartvelo, 1970. 222 p.

197. Handbook of tribology / Under the general. ed. Hebdy M., Chichinadze A.B. In 3 volumes. T.1. Theoretical basis. M.: Mashinostroenie, 1989. - 400 p.

198. Starovoitov E.I., Moskvitin V.V. On the study of the stress-strain state of two-layer metal-polymer plates under cyclic loads. Izv. Academy of Sciences of the USSR. MTT. 1986. - No. 1. - S. 116-121.

199. Starovoitov E.I. To the bending of a round three-layer metal-polymer plate // Theoretical and applied mechanics. 1986. - issue. 13. - S. 5459.

200. Suslov A.G. Technological support of contact stiffness of joints. M.: Nauka, 1977, - 100 p.

201. Sukharev I.P. Strength of hinged units of machines. Moscow: Mashinostroyeniye, 1977. - 168 p.

202. Tarikov G.P. To the solution of a spatial contact problem taking into account wear and heat release using electrical modeling // Friction and wear. -1992. -T. 13, No. 3. S. 438-442.

203. Tarnovsky Yu.M. Zhigun I.G., Polyakov V.A. Spatially reinforced composite materials. M.: Mashinostroenie, 1987. -224p.

204. Theory and practice of wear-resistant and protective-decorative coatings. Kyiv: Kyiv House of Scientific and Technical Propaganda, 1969. -36 p.

205. Warm M.I. Contact problems for bodies with circular boundaries. Lvov: High school, 1980. - 176 p.

206. Warm M.I. Determination of wear in a friction pair shaft-sleeve // Friction and wear. -1983. T. 4, No. 2. - S. 249-257.

207. Warm M.I. On the calculation of stresses in cylindrical mates // Problems of Strength. 1979. - No. 9. - S. 97-100.

208. Trapeznikov L.P. Thermodynamic potentials in the theory of creep of aging media // Izv. Academy of Sciences of the USSR. MTT. 1978. - No. 1. - S. 103-112.

209. Tribological reliability of mechanical systems / Drozdov Yu.N., Mudryak V.I., Dyntu S.I., Drozdova E.Yu. // Problems of mechanical engineering and reliability of machines. - 1997. No. 2. - P. 35-39.

210. Umansky Ya.S., Skakov Yu.A. Physics of metals. atomic structure metals and alloys. Moscow: atomizdat, 1978. - 352 p.

211. Stability of multilayer coatings for tribological applications at small subcritical deformations / Guz A.N., Tkachenko E.A., Chekhov V.N., Strukotilov V.S. // App. fur. -1996, - vol. 32, no. 10. S. 38-45.

212. Fedyukin V.K. Some topical issues of determining the mechanical properties of materials. M.: IPMash RAN. SPb, 1992. - 43 p.

213. Fedorov C.B. Development of scientific foundations energy method compatibility of statically loaded tribosystems: Abstract of the thesis. diss. . doc. those. Sciences 05.02.04 / Nat. those. University of Ukraine / Kyiv, 1996. 36 p.

214. Physical nature of creep of crystalline bodies / Indenbom V.M., Mogilevsky M.A., Orlov A.N., Rozenberg V.M. // Journal prikl. math. and those. physical 1965. - No. 1. - S. 160-168.

215. Khoroshun L.P., Saltykov N.S. Thermoelasticity of two-component mixtures. Kyiv: Nauk. Dumka, 1984. - 112 p.

216. Khoroshun L.P., Shikula E.H. Influence of component strength dispersion on the deformation of a granular composite during microfractures, Prikl. fur. 1997. - V. 33, No. 8. - S. 39-45.

217. Khusu A.P., Vitenberg Yu.R., Palmov V.A. Surface roughness (probabilistic approach). M.: Nauka, 1975. - 344 p.

218. Tsesnek L.S. Mechanics and microphysics of abrasion of surfaces. M.: Mashinostroenie, 1979. - 264 p.

219. Tsetsokho V.V. On the justification of the collocation method for solving integral equations of the first kind with weak singularities in the case of open circuits // Ill-posed problems of mathematical physics and analysis. -Novosibirsk: Nauka, 1984. S. 189-198.

220. Zuckerman S.A. Powder and composite materials. M.: Nauka, 1976. - 128 p.

221. Cherepanov G.P. Fracture mechanics of composite materials. M: Nauka, 1983. - 296 p.

222. Chernets M.V. On the issue of assessing the durability of cylindrical sliding tribosystems with boundaries close to circular // Friction and wear. 1996. - Vol. 17, No. 3. - S. 340-344.

223. Chernets M.V. About one method of rozrahunka to the resource of cylinder forging systems // Dopovshch Natsionalno!" Academy of Sciences of Ukraine. 1996, No. 1. - P. 4749.

224. Chigarev A.V., Kravchuk A.S. Contact interaction of cylindrical bodies of close radii // Materials, technologies, tools. 1998, No. 1. -S. 94-97.

225. Chigarev A.V., Kravchuk A.S. Contact problem for a hard disk and a composite plate with a cylindrical hole // Polymer Composites 98: Sat. tr. intl. scientific and technical Conf., Gomel, September 29-30, 1998 / IMMS ANB Gomel, 1998 - P. 317-321.

226. Chigarev A.V., Kravchuk A.S. Calculation of the strength of sliding bearings taking into account the rheology of the roughness of their surfaces // 53rd Int. scientific and technical conf. prof., lecturer, researcher slave. and aspir. BSPA: Sat. abstract report, part 1. Minsk, 1999 / BGPA Minsk, 1999. - S. 123.

227. Chigarev A.V., Kravchuk A.S. Determination of stresses in the calculation of the strength of machine parts bounded by cylindrical surfaces // Applied Problems of Continuum Mechanics: Sat. articles. Voronezh: Publishing House of VSU, 1999. - S. 335-341.

228. Chigarev A.V., Kravchuk A.S. Contact problem for a hard disk and a plate with a rough cylindrical hole// Contemporary Issues mechanics and applied mathematics: Sat. abstract dokl., Voronezh, April 1998 / Voronezh: VGU, 1998. p. 78

229. Chigarev A.V., Chigarev Yu.V. Self-consistent method for calculating the effective coefficients of inhomogeneous media with a continuous distribution of physical and mechanical properties // Reports of the Academy of Sciences of the USSR. 1990. -T. 313, no. 2. - S. 292-295.

230. Chigarev Yu.V. Influence of inhomogeneity on the stability and contact deformation of rheologically complex media: Abstract of the thesis. diss. .doctor of physics, -mat. Sciences: 01.02.04./ Bel agrar. those. university Minsk, 1993. - 32 p.

231. Chizhik S.A. Tribomechanics of precision contact (scanning probe analysis and computer simulation): Abstract of the thesis. diss. . doc. those. Sciences: 05.02.04. / IMMS NAIB. Gomel, 1998. - 40 p.

232. Shemyakin E.I. On one effect of complex loading // Bulletin of Moscow State University. Ser. 1. Mathematics, mechanics. 1996. - No. 5. - S. 33-38.

233. Shemyakin E.I., Nikiforovsky B.C. Dynamic destruction of solids. Novosibirsk: Nauka, 1979. - 271 p.

234. Sheremetiev M.P. Plates with reinforced edges. Lvov: From the Lv-go un-ta, 1960. - 258 p.

235. Shermergor T.D. Theory of elasticity of microinhomogeneous bodies. M.: Nauka, 1977.-400 p.

236. Shpenkov G.P. Physico-chemistry of friction. Minsk: Universitetskoe, 1991. - 397 p.

237. Shtaerman I.Ya. Contact problem of the theory of elasticity, - M.-L.: Gostekhizdat, 1949, - 270 p.

238. Shcherek M. Methodological bases of systematization of experimental tribological studies: dissertation. in the form of scientific report . doc. those. Sciences: 05.02.04/Inst. technologists of operation. Moscow, 1996. - 64 p.

239. Shcherek Mm Fun V. Methodological foundations experimental tribological research // On the nature of friction of solids: Proceedings. report International Symposium, Gomel June 8-10, 1999 / IMMS NASB. - Gomel, 1999. S. 56-57.

240. Anitescu M. Time-stepping methods for stiff multi-rigid-body dynamics with contact and friction // Fourth Intern. Congress on Industrial and Applied Mathematics, 5-6 July, 1999, Edinburg, Scotland. P. 78.

241. Bacquias G. Deposition des metaux du proupe platime // Galvano-Organo. -1979. -N499. P. 795-800.

242. Batsoulas Nicolaos D. Prediction of metallic materials creep deformation under multiaxial stress state // Steel Res. 1996. - V. 67, N 12. - P. 558-564.

243. Benninghoff H. Galvanische. Uberzuge gegen Verschleiss // Indastrie-Anzeiger.- 1978. Bd. 100, No. 23. - S. 29-30.

244. Besterci M., Iiadek J. Creep in dispersion strengthened materials on AI basis. // Cover. Prask. met., VUPM. 1993. - N 3, P. 17-28.

245. Bidmead G.F., Denies G.R. The potentialities of electrodeposition and associated processes in engineering practice // Transactions of the Institute of Metal Finishing.- 1978.-vol. 56,N3,-P. 97-106.

246. Boltzmann L. Zur theorie der elastischen nachwirkung // Zitzungsber. Acad. Wissensch. Math. -Naturwiss. Kl. 1874. - B. 70, H. 2. - S. 275-305.

247. Boltzmann L. Zur theorie der elastischen nachwirkung // Ann. Der Phys. Und Chem. 1976 - Bd. 7, H. 4. - S. 624-655.

248. Chen J.D., Liu J.H. Chern, Ju C.P. Effect of load on tribological behavior of carbon-carbon composites // J. Mater. Sei. 1996. Vol. 31, No. 5. - P. 1221-1229.

249. Chigarev A.V., Kravchuk A.S. Contact Problem of a rigid Disk and Isotropic Plate with Cylindrical Hole // Mechanika. 1997. - No. 4 (11). - P. 17-19.

250. Chigarev A.V., Kravchuk A.S. Rheology of Real Surface in Problem for interior contact of Elastic Cylinders // Abstracts of conference "Modelling"98", Praha, Czech Republic, 1998. P. 87.

251. Chigarev A.V., Kravchuk A.S. Effect of Thin Metal Coating on Contact Rigidity// Intern. Conf. on Multifield Problems, October 6-8, 1999, Stuttgart, Germany. P. 78.

252. Chigarev A.V., Kravchuk A.S. Creep of a Rough Layer in a Contact Problem for Rigid Disk and Isotropic Plate with Cylindrical Hole. //Proc. of 6th Intern. Symposium on Creep and Coupled Processes Bialowieza, September 23-25, 1998, Poland. P. 135-142.

253. Chigarev A.V., Kravchuk A.S. Wear and Roughness Creep in Contact Problem for Real Bodies. //Proc. of Intern. Conf. "Mechanika"99", Kaunas, April 8-9, 1999, Lietuva. P. 29-33.

254. Chigarev A.V., Kravchuk A.S. Influence of Roughness Rheology on Contact Rigidity // ICER"99: Proc. of Intern. Conf., Zielona Gora, 27-30 June, 1999. P. 417-421.

255. Chigarev A.V., Kravchuk A.S. Thin Homogeneous Growing Old Coating in Contact Problem for Cylinders // Proceedings of 6th International Symposium INSYCONT"02, Cracow, Poland, September 19th-20th, 2002. P. 136 - 142.

256. Childs T.H.C. The Persistence of asperities in indentation experiments // Wear. -1973, V. 25. P. 3-16.

257. Eck C., Jarusek J. On the Solvability of Thermoviscoelastic Contact Problems with Coulomb Friction, Intern. Conference on Multifield Problems, October 6-8, 1999, Stuttgart, Germany. P. 83.

258. Egan John. A new look at linear visco elasticity // Mater Letter. 1997. - V. 31, N3-6.-P. 351-357.

259. Ehlers W., Market B. Intrinsic Viscoelasticity of Porous Materials, Intern. Conference on Multifield Problems, October 6-8, 1999, Stuttgart, Germany. P. 53.

260. Faciu C., Suliciu I. A. Maxwellian model for pseudoelastic materials // Scr. met. et. mater. 1994. - V. 31, N 10. - P. 1399-1404.

261. Greenwood J., Tripp J. The elastic contact of rough spheres // Transactions of the ASME, Ser. D(E). Journal of Applied Mechanics. 1967. - Vol. 34, No. 3. - P. 153-159.

262. Hubell F.N. Chemically deposited composites a new generation of electrolyses coating // Transaction of the Institute of Metal Finishing. - 1978. - vol. 56, No. 2. - P. 65-69.

263 Hubner H., Ostermann A.E. Galvanisch und chemisch abgeschiedene funktionelle schichten //Metallo-berflache. 1979. - Bd 33, N 11. - S. 456-463.

264 Jarusek J., Eck C. Dynamic Contact Problems with Friction for Viscoelastic Bodies Existence of Solutions // Intern. Conf. on Multifield Problems, October 68,1999 Stuttgart, Germany. - P. 87.

265. Kloos K., Wagner E., Broszeit E. Nickel Siliciumcarbid-Dispersionsschichten. Teill. Tribolozische und Tribologich-Chemische Eigenschaften //Metalljberflache. - 1978. - Bd. 32, No. 8. - S. 321-328.

266. Kowalewski Zbigniew L. Effect of plastic prestrain magnitude on uniaxial tension creep of cooper at elevated temperatures, Mech. theor. i stosow. 1995. Vol. 33, N3. - P. 507-517.

267. Kravchuk A.S. Mathematical Modeling of Spatial Contact Interaction of a System of Finite Cylindrical Bodies // Technische Mechanik. 1998. - Bd 18, H 4. -S. 271-276.

268. Kravchuk A.S. Power Evaluation of the Influence of Roughness on the Value of Contact Stress for Interaction of Rough Cylinders // Archives of Mechanics. 1998.-N6. - P. 1003-1014.

269. Kravchuk A.S. Contact of Cylinders with Plastic Coating // Mechanika. 1998. -№4(15). - P. 14-18.

270. Kravchuk A.S. Determination of contact stress for composite sliding bearings // Mechanical Engineering. 1999. - No. 1. - P. 52-57.

271. Kravchuk A.S. Study of Contact Problem for Disk and Plate with Wearing Hole // Acta Technica CSAV. 1998. - 43. - P. 607-613.

272. Kravchuk A.S. Wear in Interior Contact of Elastic Composite Cylinders // Mechanika. 1999. - No. 3 (18). - P. 11-14.

273. Kravchuk A.S. Elastic deformation energy of a rough layer in a contact problem for rigid disk and isotropy plate with cylindric hole // Nordtrib"98: Proc. of the 8th Intern. Conf. on Tribology, Ebeltoft, Denmark, 7 10 June 1998. - P. 113-120.

274. Kravchuk A.S. Rheology of Real Surface in Problem for Rigid Disk and Plate with hole // Book of abstr. of Conf. NMCM98, Miskolc, Hungary, 1998, pp. 52-57.

275. Kravchuk A.S. Effect of surface rheology on contact displacement// Technische Mechanik. 1999. - Band 19, Heft N 3. - P. 239-245.

276. Kravchuk A.S. Evaluation of Contact Rigidity in the Problem for Interaction of Rough Cylinders // Mechanika. 1999. - No. 4 (19). - P. 12-15.

277. Kravchuk A.S. Contact Problem for Rough Rigid Disk and Plate with Thin Coating on Cylindrical Hole // Int. J. of Applied Mech. Eng. 2001. - Vol. 6, No. 2, P. 489-499.

278. Kravchuk A.S. Time depend nonlocal structural theory of contact of real bodies // Fifth World Congress on Computational Mechanics, Vienna July 7-12, 2002.

279. Kunin I.A. Elastic media with microstructure. V I. (One-dimensional models). -Springer Series in Solid State Sciences 26, Berlin etc. Springer-Verlag, 1982. 291 P

280. Kunin I.A. Elastic media with microstructure. VII. (Three-dimensional models). Springer Series in Solid State Sciences 44, Berlin etc. Springer-Verlag, 1983. -291 p.

281. Lee E.H., Radok J.R.M., Woodward W.B. Stress analysis for linear viscoelastic materials // Trans. soc. Rheol. 1959.-vol. 3. - P. 41-59.

282. Markenscoff X. The mechanics of thin ligaments // Fourth Intern. Congress on Industrial and Applied Mathematics, 5-6 July, 1999, Edinburg, Scotland. P. 137.

283. Miehe C. Computational Homogenization Analysis of Materials with Microstructures at Large Strains, Intern. Conf. on Multifield Problems, October 68, 1999, Stuttgart, Germany.-P. 31.

284. Orlova A. Instabilities in compressive creep in copper single crystals // Z. Metallk. 1995. - V. 86, N 10. - P. 719-725.

285. Orlova A. Dislocation slip conditions and structures in copper single crystals exhibiting instabilities in creep // Z. Metallk. 1995. - V. 86, N 10. - P. 726-731.

286. Paczelt L. Wybrane problemy zadan kontaktowych dla ukladow sprezystych, Mech. kontactu powierzehut. Wroclaw, 1988.- C. 7-48.

287 Probert S.D., Uppal A.H. Deformation of single and multiple asperities on metal surface // Wear. 1972. - V. 20. - P.381-400.

288. Peng Xianghen, Zeng Hiangguo. A constitutive model for coupled creep and plasticity // Chin. J. Appl. Mech. 1997. - V. 14, N 3. - P. 110-114.

289. Pleskachevsky Yu. M., Mozharovsky V.V., Rouba Yu.F. Mathematical models of quasi-static interaction between fibrous composite bodies // Computational methods in contact mechanics III, Madrid, 3-5 Jul. 1997. P. 363372.

290. Rajendrakumar P.K., Biswas S.K. Deformation due to contact between a two-dimensional rough surface and a smooth cylinder // Tribology Letters. 1997. - N 3. -P. 297-301.

291. Schotte J., Miehe C., Schroder J. Modeling the Elastoplastic Behavior of Copper Thin Films On Substrates, Intern. Conf. on Multifield Problems, October 6-8, 1999, Stuttgart, Germany. P. 40.

292 Speckhard H. Functionelle Galvanotechnik eine Einfuhrung. - Oberflache -Surface. - 1978. - Bd 19, N 12. - S. 286-291.

293. Still F.A., Dennis J.K. Electrodeposited wear resistant coatings for hot forging dies // Metallurgy and Metal Forming, 1977, Vol. 44, No. 1, p. 10-12.

294. Volterra Y. Lecons sur les fonctions de lisnes. Paris: Gauther - Villard, 1913. -230 p.

295. Volterra V. Sulle equazioni integro-differenziali, della theoria dell elasticita // Atti Realle Academia dei Lincei Rend. 1909. - v. 18, No. 2. - P. 295-301.

296. Wagner E., Brosgeit E. Tribologische Eigenschaften von Nickeldispersionsschichten. Grundiagen und Anwendungsbeispiele aus der Praxis // Schmiertechnik+Tribology. 1979. - Bd 26, N 1. - S. 17-20.

297. Wang Ren, Chen Xiaohong. The progress of research on visco-elastic constitutive relations of polymers // Adv. Mech. 1995. - V 25, N3. - P. 289-302.

298. Xiao Yi, Wang Wen-Xue, Takao Yoshihiro. Two dimensional contact stress analysis of composite laminates with pinned joint // Bull. Res. Inst. Appl. Mech. -1997. -N81. - p. 1-13.

299. Yang Wei-hsuin. The contact problem for viscoelastic bodies // Journ. Appl. Mechanics, Pap. No. 85-APMW-36 (preprint).

Please note the above scientific texts posted for review and obtained through recognition of original texts of dissertations (OCR). In this connection, they may contain errors related to the imperfection of recognition algorithms. AT PDF files dissertations and abstracts that we deliver, there are no such errors.

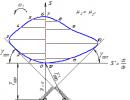

Stresses in the contact area under simultaneous loading with normal and tangential forces. Stresses determined by the photoelasticity method

Mechanics of contact interaction deals with the calculation of elastic, viscoelastic and plastic bodies in static or dynamic contact. The mechanics of contact interaction is a fundamental engineering discipline, mandatory in the design of reliable and energy-saving equipment. It will be useful in solving many contact problems, for example, wheel-rail, in the calculation of clutches, brakes, tires, plain and rolling bearings, internal combustion engines, joints, seals; in stamping, metalworking, ultrasonic welding, electrical contacts, etc. It covers a wide range of tasks, ranging from strength calculations of tribosystem interface elements, taking into account the lubricating medium and material structure, to applications in micro- and nanosystems.

Story

The classical mechanics of contact interactions is associated primarily with the name of Heinrich Hertz. In 1882, Hertz solved the problem of the contact of two elastic bodies with curved surfaces. This classical result still underlies the mechanics of contact interaction today. Only a century later, Johnson, Kendal and Roberts found a similar solution for adhesive contact (JKR - theory).

Further progress in the mechanics of contact interaction in the middle of the 20th century is associated with the names of Bowden and Tabor. They were the first to point out the importance of taking into account the surface roughness of the bodies in contact. Roughness leads to the fact that the actual area of contact between rubbing bodies is much less than the apparent area of contact. These ideas have significantly changed the direction of many tribological studies. The work of Bowden and Tabor gave rise to a number of theories of the mechanics of the contact interaction of rough surfaces.

Pioneer work in this area is the work of Archard (1957), who came to the conclusion that when elastic rough surfaces are in contact, the contact area is approximately proportional to the normal force. Further important contributions to the theory of contact between rough surfaces were made by Greenwood and Williamson (1966) and Persson (2002). The main result of these works is the proof that the actual contact area of rough surfaces in a rough approximation is proportional to the normal force, while the characteristics of an individual microcontact (pressure, microcontact size) weakly depend on the load.

Classical problems of contact interaction mechanics

Contact between a ball and an elastic half-space