Defects in crystals physics presentation. Defects in crystal lattices. Defects in crystals

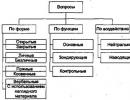

Defects in crystals are divided into:

Zero-dimensional

One-dimensional

2D

Point defects (zero-dimensional) - periodicity violations at lattice points isolated from each other; in all three dimensions they do not exceed one or more interatomic distances (lattice parameters). Point defects are vacancies, atoms in interstices, atoms in the sites of a “foreign” sublattice, impurity atoms in sites or interstices.

Jobs- the absence of an atom or ion in a node of the crystal lattice; Embedded or interstitial atoms or ions can be either intrinsic or impurity atoms or ions that differ from the main atoms in size or valency. Substitution impurities replace the particles of the main substance at the lattice sites.

Linear(one-dimensional) defects – The main line defects are dislocations. The a priori concept of dislocations was first used in 1934 by Orowan and Theiler in the study of plastic deformation of crystalline materials, to explain the large difference between the practical and theoretical strength of the metal. Dislocation- these are defects in the crystal structure, which are lines along and near which the regular arrangement of atomic planes characteristic of a crystal is violated.

Surface defects of the crystal lattice. The surface lattice defects include stacking faults and grain boundaries.

Output: all types of defects, regardless of the cause of their occurrence, lead to a violation of the equilibrium state of the lattice and increase its internal energy.

Defects in crystals. The crystal is filled with defects. How do defects affect the strength of crystals. They lower strength, hundreds, thousands of times. But, as the deformation of the crystal increases, the number of defects in it also increases. And since the defects interact with each other, the more there are, the more difficult it is for them to move in the crystal. It turns out a paradox: if there is a defect in the crystal, the crystal is deformed and destroyed more easily than if there is no defect. And if there are too many defects, then the crystal again becomes strong, and the more defects, the more ordered it is. So, if we learn to control the number and location of defects, we can control the strength of materials.

slide 21 from the presentation "Crystal". The size of the archive with the presentation is 1397 KB.Chemistry Grade 11

summary other presentations"Classification of substances" - Distribute the substances. Simple substances are metals. Gold. Zn. Sulfur. Classification of substances. CO. Cl2. Metals and non-metals. Eliminate the excess classification characteristic substance. Simple substances are non-metals. Na2o. O2. Silver. O.S.Gabrielyan. Grade 11. Sort the substances into classes.

"Circulation of elements in nature" - Denitrifying bacteria. vegetable proteins. bacteria. Atmosphere. Lightning. The nitrogen cycle. Big circle. Decaying organisms. Phosphorus is found in various minerals in the form of inorganic phosphathion (PO43-). Phosphorus is part of the genes and molecules that carry energy into cells. The dominant form of oxygen in the atmosphere is the O2 molecule. Artificial phosphate fertilizers; detergents. Phosphates are soluble in water but not volatile.

"Dispersed systems chemistry" - Dispersed system solid - liquid. Porous chocolate. cartilage. Smoke. Minerals. Medium and phase are liquids. Ceramics. Syneresis determines the shelf life of food, medical and cosmetic gels. In medicine. Fizzy drinks. Dispersed gas-liquid system. Smog. IN Food Industry. Foam rubber. Zoli Geli. true solutions. Polystyrene. Suspensions. Dispersed system liquid - gas. Gels. The phase and medium are easily separated by settling.

"Periodic Chemistry" - I. Döbereiner, J. Dumas, French chemist A. Chancourtua, eng. chemists W. Odling, J. Mendeleev on the place of an element in a system; the position of the element is determined by the period and group numbers. the prediction of "ekaaluminum" (the future Ga, discovered by P. Lecoq de Boisbaudran in 1875), "ecabor" (Sc, discovered by the Swedish scientist L. Nilsson in 1879), and "ecasilience" (Ge, discovered by the German scientist K. Winkler in 1886). 1829 - "triads" Döbereiner 1850 "differential systems" Pettenkofer and Dumas. 1864 Meyer - a table showing the ratio of atomic weights for several characteristic groups of elements. Newlands - the existence of groups of elements similar in chemical properties. Kolchina N. 11 "A". Periodic law, Periodic system chemical elements D. I. Mendeleev.

"Means of hygiene and cosmetics" - As a detergent. The action of the second group of deodorants is based on the partial suppression of perspiration processes. For artists Powder Hydrogen peroxide. The meaning of words. Cosmetic decorative powders are multicomponent mixtures. Cosmetical tools. Done by: Svetlana Shesterikova, 11th grade student, secondary school No. 186. A bit of history. I stage. Detergent functions. Soaps and detergents.

"Silver chemistry" - Silver nitrate, or lapis - crystals of the rhombic system. Wart after cauterization with silver nitrate. Silver in art. AgNO3 is very soluble. And what dangers is fraught with a mysterious metal? Forms alloys with many metals. Most silver salts are slightly soluble in water, and all soluble compounds are toxic. Technologies for obtaining pure metallic silver.

Defects in crystals are called violations of the ideal crystal structure. Such a violation may consist in the replacement of an atom of a given substance by a foreign atom (impurity atom) (Fig. 1, a), in the introduction of an extra atom into an interstice (Fig. 1, b), in the absence of an atom in the site (Fig. 1, c). Such defects are called pinpoint.They cause lattice violations that propagate over distances on the order of several periods.

In addition to point defects, there are defects concentrated near certain lines. They are called linear defects or dislocations. Defects of this type disrupt the regular alternation of crystal planes.

The simplest types of dislocations are regional And screw dislocations.

An edge dislocation is caused by an extra crystalline half-plane embedded between two adjacent layers of atoms (Fig. 2). A screw dislocation can be represented as a result of cutting a crystal along a half-plane and a subsequent shift of the lattice parts lying on opposite sides of the cut towards each other by the value of one period (Fig. 3).

Defects have a strong effect on physical properties crystals, including their strength.

The initially existing dislocation moves along the crystal under the influence of the stresses created in the crystal. The movement of dislocations is hindered by the presence of other defects in the crystal, for example, the presence of impurity atoms. Dislocations are also decelerated when crossing each other. An increase in the density of dislocations and an increase in the concentration of impurities leads to a strong deceleration of dislocations and the cessation of their movement. As a result, the strength of the material increases. For example, an increase in the strength of iron is achieved by dissolving carbon atoms in it (steel).

Plastic deformation is accompanied by the destruction of the crystal lattice and the formation of a large number of defects that prevent the movement of dislocations. This explains the hardening of materials during their cold processing.

slide 1

Physics solid body. Part 2.

Real crystals - (just like "real boys") are perfect crystals that grow in the wrong places.

slide 2

Growth of crystals You know, of course, that water (under normal pressure) freezes at 0°. If the temperature drops, then exactly at 0 ° the water will begin to freeze, turn into ice crystals. Until all the water freezes, its temperature will not drop further. If, on the other hand, an ice crystal is heated to 0°, it will remain unchanged. As soon as the temperature reaches 0°, the crystal will immediately begin to melt. No matter how much we heat further, the temperature of the ice will not rise until all the ice has melted. Only when the whole crystal, having melted, turns into water (in other words, until the system of all particles disintegrates), the temperature of the water can begin to rise. Any crystalline substance melts and crystallizes at a strictly defined melting point: iron - at 1530 °, tin - at 232 °, quartz - at 1713 °, mercury - at minus 38 °. Non-crystalline solids do not have a constant melting point (and hence, crystallization temperature), when heated, they gradually soften.

slide 3

Ways to grow crystals One of them is the cooling of a saturated hot solution. At each temperature, no more than a certain amount of a substance can dissolve in a given amount of solvent (for example, in water). If the solution is cooled slowly, few nuclei are formed, and, gradually overgrowing from all sides, they turn into beautiful crystals of the correct shape. With rapid cooling, many nuclei are formed, and particles from the solution will “pour” onto the surface of growing crystals, like peas from a torn bag; of course, correct crystals will not be obtained in this case, because the particles in solution may simply not have time to “settle” on the surface of the crystal in their place. Another method for obtaining crystals is the gradual removal of water from a saturated solution. The "extra" substance crystallizes. And in this case, the slower the water evaporates, the better the crystals are obtained.

slide 4

The third method is the growth of crystals from molten substances by slowly cooling the liquid. When using all methods, the best results are obtained if a seed is used - a small crystal of the correct shape, which is placed in a solution or melt. In this way, for example, ruby crystals are obtained. Growth of crystals of precious stones is carried out very slowly, sometimes for years. If, however, to accelerate crystallization, then instead of one crystal, a mass of small ones will turn out. This method can only be carried out in special devices. Currently, more than half of the technically important crystals are grown from the melt. One of the most widely used industrial methods for obtaining semiconductor and other single crystals is the Czochralski method. Designed in 1918. The source material (charge) is loaded into a refractory crucible and heated to a molten state. Then the seed crystal in the form of a thin rod with a diameter of several mm is placed in a cooled crystal holder and immersed in the melt.

slide 5

Jan Czochralski (1885 - 1953) - Polish chemist, inventor of the now widely known method of growing single crystals from a melt by pulling them up from a free surface, later named after him. According to some accounts, Czochralski discovered his famous method in 1916 when he accidentally dropped his pen into a crucible of molten tin. Pulling the pen out of the crucible, he found that a thin thread of solidified tin was trailing behind the metal pen. By replacing the pen nib with a microscopic piece of metal, Czochralski became convinced that the metal thread thus formed had a single-crystal structure. In experiments conducted by Czochralski, single crystals were obtained with a size of about one millimeter in diameter and up to 150 cm in length.

slide 6

Crystal Defects Describing the structure of crystals, we have so far used them ideal models. The difference between real crystals and ideal ones is that real crystals do not have a regular crystal lattice. They always contain violations of strict periodicity in the arrangement of atoms. These disturbances are called defects in crystals. Defects are formed during the growth of crystals under the influence of thermal motion of molecules, mechanical influences, irradiation with particle flows, due to the presence of impurities, etc. Any violation of the translational symmetry of a crystal - the ideal periodicity of the crystal lattice - is called a crystal defect. There are several types of defects by dimension. Namely, there are zero-dimensional (point), one-dimensional (linear), two-dimensional (flat) and three-dimensional (volumetric) defects.

Slide 7

Zero-dimensional (or point) crystal defects include all defects that are associated with the displacement or replacement of a small group of atoms (intrinsic point defects), as well as with impurities. They arise during heating, alloying, in the process of crystal growth and as a result of radiation exposure. Can also be made as a result of implantation. The properties of such defects and the mechanisms of their formation are the most studied, including motion, interaction, annihilation, and evaporation. Defects, called point defects, arise when one of the atoms of the crystal lattice is replaced by an impurity atom (a), the introduction of an atom between the lattice nodes (b) or as a result of the formation of vacancies - the absence of an atom in one of the lattice nodes (c).

Slide 8

Substitutional impurities, replacing the particles of the main substance at the lattice sites, are introduced into the lattice the easier, the closer the atomic (ionic) radii of the impurity and the main substance. Interstitial impurities occupy interstices and, moreover, the easier it is, the greater the volume of space between atoms. Embedded can be both intrinsic and impurity atoms or ions that differ from the main atoms in size or valence. If a foreign atom is at a site, then this is a substitution defect; if it is at an interstice, then this is an interstitial atom. The equilibrium positions occupied by interstitial atoms depend on the material and type of the lattice. Neighboring atoms in the nodes of the crystal lattice are somewhat displaced, causing a slight deformation. Vacancies are the most important type of point defects; they accelerate all processes associated with the movement of atoms: diffusion, sintering of powders, etc. In commercially pure metals, point defects increase the electrical resistance, but have almost no effect on the mechanical properties. Only when high concentrations defects in irradiated metals, plasticity decreases and other properties noticeably change.

Slide 9

How do spot defects appear? According to the basic principles of statistical physics, even when the average kinetic energy of atoms is very small, there will always be a certain number of atoms with a greater energy, sufficient to move an atom out of a lattice site. Moving through the crystal and giving part of its energy to other atoms, such an atom can be located in the interstices. The combination of an atom in an interstices and a vacancy is called a Frenkel defect (or a Frenkel pair). The vacancy and the interstitial atom are bound by significant elastic forces.

Frenkel defects easily arise in crystals containing significant interatomic voids. Substances with the structure of diamond or rock salt can serve as an example of such crystals.

Slide 10

Schottky point defects are mainly found in close-packed crystals, where the formation of interstitial atoms is difficult or energetically unfavorable. Some atoms from the near-surface layer as a result of thermal motion can leave the crystal to the surface (Fig.). The vacancy at the vacated site can then migrate into the bulk of the crystal. The formation of Schottky defects reduces the density of the crystal, since its volume increases at a constant mass, while during the formation of Frenkel defects, the density remains unchanged, since the volume of the entire body does not change.

Walter Hermann Schottky (1886 - 1976) - the famous German physicist, in 1915 invented the vacuum tube with a screening grid and in 1919 the tetrode. In 1938, Schottky formulated a theory predicting the Schottky effect, now used in Schottky diodes.

slide 11

Thus, while representing a far from perfect, ordered, and somewhat monotonous sequence of alternating positive and negative ions, real crystals contain a wide range of interesting point defects, which, as we will see, can greatly affect many of their properties. As we have already said, these are intrinsic defects, the concentration of which depends on temperature, and, in addition, non-intrinsic, impurity defects, which are either present by chance or added purposefully during crystal growth. All these defects can be considered as quasiparticles. Like real particles in a vacuum, they can move and interact with each other over long distances to form more complex structures.

slide 12

Transfer Processes in Crystals It is often mistakenly assumed that common alkali halide compounds such as sodium chloride and potassium chloride are insulators, but in fact they are relatively good conductors, this is especially true at elevated temperatures. The fact of the existence of conductivity, as well as the fact that both self-diffusion and diffusion of impurity ions quite easily occur in ionic solids, serve as irrefutable evidence of the presence of point defects in them. Many of these materials do not have electronic conductivity - measurements show that the conductivity is due to ion migration. However, without the existence of vacancies or interstitial atoms, the movement of ions in such a classical ionic conductor is impossible: this would require too much energy. Due to defects and their movements (Fig.), the process of ion movement turns into an exchange of places between the ion and the defect; while the amount of required energy decreases.

slide 13

Diffusion (Latin diffusio - spreading, spreading, dispersion, interaction) is the process of mutual penetration of molecules of one substance between the molecules of another, leading to spontaneous alignment of their concentrations throughout the occupied volume. In some situations, one of the substances already has an equal concentration and one speaks of the diffusion of one substance in another. In this case, the transfer of a substance occurs from a region with a high concentration to a region with a low concentration (along the concentration gradient). In crystals, both intrinsic lattice atoms (self-diffusion or homodiffusion) and atoms of other chemical elements dissolved in the substance (impurity or heterodiffusion) can diffuse, as well as point defects in the crystal structure - interstitial atoms and vacancies.

Slide 14

Diffusion is a process at the molecular level and is determined by the random nature of the movement of individual molecules. The diffusion rate is therefore proportional to the average velocity of the molecules. If in a mixture of gases the mass of one molecule is four times greater than the other, then such a molecule moves twice as slowly compared to its movement in a pure gas. Accordingly, its diffusion rate is also lower. This difference in diffusion rates between light and heavy molecules is used to separate substances with different molecular weights. An example is the separation of isotopes. If a gas containing two isotopes is passed through a porous membrane, the lighter isotopes permeate the membrane faster than the heavier ones. For better separation, the process is carried out in several stages. This process has been widely used to separate uranium isotopes (separation of 235U from the bulk of 238U). (Currently, a centrifugation method is used to separate the isotopes of uranium, in which a gas containing uranium is rotated very quickly and, due to the difference in the mass of the molecules, the isotopes are separated, which are then transferred back to the metal.)

slide 15

Diffusion phenomenologically obeys Fick's laws. Fick's 1st law establishes the proportionality of the diffusion flux of particles to the gradient of their concentration; Fick's 2nd law describes the change in concentration due to diffusion. The phenomenon of diffusion was first studied by the Wurzburg scientist A. Fick using salt solutions as an example. Fick, through careful research, showed that the free diffusion of salt solutions occurs according to laws that are completely analogous to the laws of heat propagation in solids.

slide 16

Diffusion in Crystals Some general crystallographic features of the diffusion process are quite obvious if we take into account the geometry of the crystal. First of all, diffusion almost always occurs gradually, and the length of the elementary "steps" is of the order of one atomic diameter, i.e., several angstroms. Atoms move by jumping from one position in the lattice to another. In sum, these elementary jumps ensure the movement of atoms over long distances. Let us find out what is the mechanism of individual atomic jumps. There are several possible schemes: the movement of vacancies, the movement of interstitial atoms, or some kind of mutual exchange of places between atoms (Fig.).

Atomic displacements that lead to diffusion: a – movement of vacancies; b – motion of interstitial atoms; c – exchange of places of two atoms; d - ring exchange of places of four atoms

Slide 17

Based on the concept of point defects in crystals, Frenkel proposed two main diffusion mechanisms in solids: vacancy (Fig. a: an atom moves, exchanging places with a vacancy) and interstitial (Fig. b: an atom moves along interstices). Small (in size) impurity atoms move in the second way, and all the rest in the first way: this is the most common diffusion mechanism.

Yakov Ilyich Frenkel (1894 - 1952) - Soviet scientist, theoretical physicist, one of the founders of solid state physics. From 1921 until the end of his life, Frenkel worked at the Leningrad Institute of Physics and Technology. Beginning in 1922, Frenkel published a new book literally every year. He became the author of the first course in theoretical physics in the USSR.

Slide 18

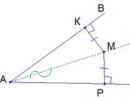

Dislocations A dislocation is a linear defect in the crystal lattice of a solid, which is the presence of an "extra" atomic half-plane. The simplest visual model of an edge dislocation is a book with a part torn off from one of the inner pages. Then, if the pages of the book are likened to atomic planes, then the edge of the torn off part of the page models the dislocation line. A distinction is made between screw and edge dislocations.

Slide 19

In order for a dislocation to form in an ideal crystal, it is necessary to produce a shift in some part of the slip plane

The dislocation density varies over a wide range and depends on the state of the material. After careful annealing, the dislocation density is low; in crystals with a strongly deformed crystal lattice, the dislocation density reaches very high values.

Slide 20

The dislocation density largely determines the plasticity and strength of the material. If the density is less than a certain value, then the resistance to deformation increases sharply, and the strength approaches the theoretical one. Thus, an increase in strength is achieved by creating a metal with a defect-free structure, and, on the other hand, by increasing the density of dislocations, which hinders their movement.

slide 21

During plastic deformation, one part of the crystal moves relative to the other under the action of shear stresses. When the loads are removed, the shift remains, i.e. plastic deformation occurs. The application of a shear stress leads to the displacement of an edge dislocation, and the displacement of its axis by one translation means a change in the half-plane forming in this moment dislocation. The movement of an edge dislocation through the entire crystal will lead to a shift of a part of the crystal by one interatomic distance. The result of this is the plastic deformation of the crystal (Fig.), i.e., the parts of the crystal are displaced relative to each other by one translation.

A metal in a stressed state, under any type of loading, always experiences normal and tangential stresses. The growth of normal and shear stresses leads to different consequences. The growth of normal stresses leads to brittle fracture. Plastic deformation is caused by tangential stresses.

slide 22

An increase in strength is achieved by creating a metal with a defect-free structure, as well as by increasing the density of dislocations, which hinders their movement. At present, crystals without defects have been created - whiskers up to 2 mm long, 0.5 ... 20 μm thick - "whiskers" with a strength close to theoretical. Dislocations affect not only strength and plasticity, but also other properties of crystals. With an increase in the density of dislocations, their optical properties, the electrical resistance of the metal increases. Dislocations increase the average diffusion rate in a crystal, accelerate aging and other processes, reduce chemical resistance, therefore, as a result of treating the crystal surface with special substances, pits form at the exit points of dislocations.

slide 23

Epitaxy is a regular growth of one crystalline material on another (from the Greek επι - on and ταξισ - order), i.e., the oriented growth of one crystal on the surface of another (substrate). The minimum energy is expended if the crystal grows along a screw dislocation.

slide 24

Thanks for attention!

slide 1

PROPERTIES OF DEFECTS AND THEIR ENSEMBLES IN CONDENSED MATTER Solid State Radiation Physicsslide 2

Contents Section 1 Types of individual elementary defects and their properties. Defects in simple substances 1.1. Classification of defects in simple substances 1.1.1. Interstices 1.1.2. Vacancies in covalent compounds 1.1.3. Characteristics of point defects 1.1.4. Interstices in simple substances and their characteristics 1.1.5. Packaging defects 1.1.6. Disordered alloys. Impurity defects 1.1.7. Ordered alloys. Types of lattices with ordering 1.2. Equilibrium and non-equilibrium defects 1.2.1. Equilibrium concentration of point defects in simple substances 1.3. Defects in ordering alloys 1.3.1. Long-range order metric in ordering alloys 1.3.2. Short-range order metric in ordering alloys. Relationship between long-range order and average value of short-range order in ordered alloys 1.3.3. Temperature dependence of the concentration of equilibrium substitutional defects in ordered alloys 1.3.4. Temperature dependence of the concentration of equilibrium vacancies in ordering alloys

Contents Section 1 Types of individual elementary defects and their properties. Defects in simple substances 1.1. Classification of defects in simple substances 1.1.1. Interstices 1.1.2. Vacancies in covalent compounds 1.1.3. Characteristics of point defects 1.1.4. Interstices in simple substances and their characteristics 1.1.5. Packaging defects 1.1.6. Disordered alloys. Impurity defects 1.1.7. Ordered alloys. Types of lattices with ordering 1.2. Equilibrium and non-equilibrium defects 1.2.1. Equilibrium concentration of point defects in simple substances 1.3. Defects in ordering alloys 1.3.1. Long-range order metric in ordering alloys 1.3.2. Short-range order metric in ordering alloys. Relationship between long-range order and average value of short-range order in ordered alloys 1.3.3. Temperature dependence of the concentration of equilibrium substitutional defects in ordered alloys 1.3.4. Temperature dependence of the concentration of equilibrium vacancies in ordering alloys

slide 3

Contents Section 2. Description of defects in the crystal structure in the framework of the theory of elasticity 2.1. Fundamentals of continuum mechanics 2.1.1. Definitions 2.1.2. Hooke's law 2.1.3. Hooke's law in a generalized form 2.1.4. General form of equations in absolute displacements 2.2. Displacement of atoms in a crystal lattice with point defects. Volume change 2.3. Behavior of a defect in an external bias field 2.4. Density of internal forces equivalent to the center of dilatation 2.5. Interaction of defects with an external elastic field 2.6. Elastic interaction point defects 2.7. continuous distribution point defects in an elastic field 2.8. Crystal flow. Creep 2.9. Kinetics of pores in a crystal 2.10. Instability of a homogeneous distribution of point defects 2.11. Dislocations 2.12. Plastic deformation of crystals 2.13. One-dimensional dislocation model – the Frenkel–Kontorova model

Contents Section 2. Description of defects in the crystal structure in the framework of the theory of elasticity 2.1. Fundamentals of continuum mechanics 2.1.1. Definitions 2.1.2. Hooke's law 2.1.3. Hooke's law in a generalized form 2.1.4. General form of equations in absolute displacements 2.2. Displacement of atoms in a crystal lattice with point defects. Volume change 2.3. Behavior of a defect in an external bias field 2.4. Density of internal forces equivalent to the center of dilatation 2.5. Interaction of defects with an external elastic field 2.6. Elastic interaction point defects 2.7. continuous distribution point defects in an elastic field 2.8. Crystal flow. Creep 2.9. Kinetics of pores in a crystal 2.10. Instability of a homogeneous distribution of point defects 2.11. Dislocations 2.12. Plastic deformation of crystals 2.13. One-dimensional dislocation model – the Frenkel–Kontorova model

slide 4

Contents Section 3. Radiation defects 3.1. Methods for CREATING RADIATION DEFECTS 3.1.1. Irradiation in the reactor 3.1.2. Irradiation at heavy ion accelerators 3.1.3. Irradiation in a high-voltage electron microscope 3.1.4. Main advantages and disadvantages of expressive methods of radiation testing 3.2. Primary processes of interaction of particles and radiation with a solid body 3.2.1. General representations about the processes of interaction of particles with a solid body 3.2.2. Interaction of neutrons with matter 3.2.3. Interaction of accelerated ions with matter 3.2.4. Distribution by depth of penetration of implanted ions and defects created by ions 3.2.5. Interaction of electrons with matter 3.2.6. Interaction - quanta with matter 3.3. Basic conditions for the reproducibility of the phenomena of reactor damage during irradiation at the accelerator

Contents Section 3. Radiation defects 3.1. Methods for CREATING RADIATION DEFECTS 3.1.1. Irradiation in the reactor 3.1.2. Irradiation at heavy ion accelerators 3.1.3. Irradiation in a high-voltage electron microscope 3.1.4. Main advantages and disadvantages of expressive methods of radiation testing 3.2. Primary processes of interaction of particles and radiation with a solid body 3.2.1. General representations about the processes of interaction of particles with a solid body 3.2.2. Interaction of neutrons with matter 3.2.3. Interaction of accelerated ions with matter 3.2.4. Distribution by depth of penetration of implanted ions and defects created by ions 3.2.5. Interaction of electrons with matter 3.2.6. Interaction - quanta with matter 3.3. Basic conditions for the reproducibility of the phenomena of reactor damage during irradiation at the accelerator

slide 5

Contents Section 4. Theoretical comparison of the structure of random fields of radiation defects formed upon irradiation with fast particles in film samples 4.1. Cascade of atomic collisions. Individual characteristics 4.2. Random field of defects. Damage statistics 4.3. Sparse cascade model 4.4. Model of dense cascades 4.5. Simulation parameters 4.6. Simulation relations for model PVA spectra 4.7. Method for determining the time resource of superconducting compounds 4.8. Calculation of characteristics of the damage field during irradiation of thin films with ions and neutrons with a spectrum close to the real TNR spectrum

Contents Section 4. Theoretical comparison of the structure of random fields of radiation defects formed upon irradiation with fast particles in film samples 4.1. Cascade of atomic collisions. Individual characteristics 4.2. Random field of defects. Damage statistics 4.3. Sparse cascade model 4.4. Model of dense cascades 4.5. Simulation parameters 4.6. Simulation relations for model PVA spectra 4.7. Method for determining the time resource of superconducting compounds 4.8. Calculation of characteristics of the damage field during irradiation of thin films with ions and neutrons with a spectrum close to the real TNR spectrum

slide 6

Introduction "Physics of a Real Solid State" studies physical phenomena and processes caused by or arising from a high content of defects in a solid, is trying to develop predictive theories that determine the characteristics of a solid. All areas of application and "forced" use of a solid, one way or another, are determined by structural defects. The simplest examples: the conductivity of an ideal solid is zero; the critical current in superconductors is also equal to zero in the absence of pinning of the system of vortices on structural defects. An important direction is the controlled introduction of impurities and defects into the matrix, as well as the radiation-stimulated change in the structure. The beginning of the intensive development of this direction corresponds to the appearance of semiconductor devices. This direction can be called "Physical technology" since the design and creation of new instruments and tools of researchers is determined by the development of a detailed physical picture of the processes, the interpretation of the measured values. The natural decrease in the size of the objects under study and new measurement capabilities have led to the emergence of a new direction "Nanosystems". The controlled introduction of impurities and defects into the matrix is also of physical interest for the analysis of the applicability of certain concepts of condensed matter physics. For example, to analyze the mechanism of superconductivity in compounds with the A15 structure, HTSC.

Introduction "Physics of a Real Solid State" studies physical phenomena and processes caused by or arising from a high content of defects in a solid, is trying to develop predictive theories that determine the characteristics of a solid. All areas of application and "forced" use of a solid, one way or another, are determined by structural defects. The simplest examples: the conductivity of an ideal solid is zero; the critical current in superconductors is also equal to zero in the absence of pinning of the system of vortices on structural defects. An important direction is the controlled introduction of impurities and defects into the matrix, as well as the radiation-stimulated change in the structure. The beginning of the intensive development of this direction corresponds to the appearance of semiconductor devices. This direction can be called "Physical technology" since the design and creation of new instruments and tools of researchers is determined by the development of a detailed physical picture of the processes, the interpretation of the measured values. The natural decrease in the size of the objects under study and new measurement capabilities have led to the emergence of a new direction "Nanosystems". The controlled introduction of impurities and defects into the matrix is also of physical interest for the analysis of the applicability of certain concepts of condensed matter physics. For example, to analyze the mechanism of superconductivity in compounds with the A15 structure, HTSC.

Slide 7

A number of problematic problems in the physics of condensed systems are of a fundamental nature Prediction of the mechanical properties of real solids, including those in intense radiation fields; Electrical properties and phenomena in condensed systems with a high content of defects; Mechanisms of superconductivity, including high-temperature, improvement of critical parameters of superconductors; Electronic and photonic properties of organic semiconductors and crystals

A number of problematic problems in the physics of condensed systems are of a fundamental nature Prediction of the mechanical properties of real solids, including those in intense radiation fields; Electrical properties and phenomena in condensed systems with a high content of defects; Mechanisms of superconductivity, including high-temperature, improvement of critical parameters of superconductors; Electronic and photonic properties of organic semiconductors and crystals

Slide 8

Slide 9

Classification of defects of simple substances. Definition: Any disturbance or distortion in the regularity of the arrangement of the atoms of the crystal is considered a defect in the crystal lattice. The following types of individual defects are distinguished: Thermal motion of atoms Interstitial atoms and vacancies Impurity atoms Crystal boundary Polycrystals Dislocations Static lattice displacements near a defect

Classification of defects of simple substances. Definition: Any disturbance or distortion in the regularity of the arrangement of the atoms of the crystal is considered a defect in the crystal lattice. The following types of individual defects are distinguished: Thermal motion of atoms Interstitial atoms and vacancies Impurity atoms Crystal boundary Polycrystals Dislocations Static lattice displacements near a defect

slide 10

1. Thermal motion of atoms deviation of atoms from the equilibrium position; this is a thermodynamic equilibrium type of a defect that has a dynamic character.

1. Thermal motion of atoms deviation of atoms from the equilibrium position; this is a thermodynamic equilibrium type of a defect that has a dynamic character.

slide 11

2. Interstitial atoms and vacancies. These defects tend to be in equilibrium. The characteristic relaxation time to the equilibrium state can be quite long. Indeed, the process of diffusion of defects, which determines their distribution in a solid, is a thermally activated process; therefore, at insufficiently high temperatures, nonequilibrium states of systems of these defects often occur. A significant difference between systems of point defects is the presence of their interaction with each other (through the atoms of the matrix), which leads, in particular, to the formation of their complexes (ensembles), condensate in the matrix, i.e. the equilibrium state of a system of point defects in most cases is inhomogeneous in space (for example, vacancies - an ensemble of vacancies - a pore).

2. Interstitial atoms and vacancies. These defects tend to be in equilibrium. The characteristic relaxation time to the equilibrium state can be quite long. Indeed, the process of diffusion of defects, which determines their distribution in a solid, is a thermally activated process; therefore, at insufficiently high temperatures, nonequilibrium states of systems of these defects often occur. A significant difference between systems of point defects is the presence of their interaction with each other (through the atoms of the matrix), which leads, in particular, to the formation of their complexes (ensembles), condensate in the matrix, i.e. the equilibrium state of a system of point defects in most cases is inhomogeneous in space (for example, vacancies - an ensemble of vacancies - a pore).

slide 12

3. Atoms of impurities Impurities, even at low concentrations, can significantly affect the properties of a crystal, for example, they make a significant contribution to the conductivity of semiconductors The density of atoms in condensed systems is 1022–1023 atoms/cm - 1020 atom/cm3.

3. Atoms of impurities Impurities, even at low concentrations, can significantly affect the properties of a crystal, for example, they make a significant contribution to the conductivity of semiconductors The density of atoms in condensed systems is 1022–1023 atoms/cm - 1020 atom/cm3.

slide 13

4. Crystal boundary This defect leads to distortions even inside the matrix and to the violation of crystal symmetry in the regions adjacent to the boundary. Pattern of grains in a polycrystal 5. Polycrystals grains or crystallites with different orientations. The grain volume is larger than the physically representative volume. The transverse grain size is about 10-3 10-6 cm The properties of polycrystals are determined both by the crystalline grains themselves and by grain boundaries. If the grains are small and randomly oriented, then the anisotropy of properties, which is characteristic, for example, of a single crystal, does not appear in polycrystals. If there is a certain grain orientation, then the polycrystal is textured and has anisotropy.

4. Crystal boundary This defect leads to distortions even inside the matrix and to the violation of crystal symmetry in the regions adjacent to the boundary. Pattern of grains in a polycrystal 5. Polycrystals grains or crystallites with different orientations. The grain volume is larger than the physically representative volume. The transverse grain size is about 10-3 10-6 cm The properties of polycrystals are determined both by the crystalline grains themselves and by grain boundaries. If the grains are small and randomly oriented, then the anisotropy of properties, which is characteristic, for example, of a single crystal, does not appear in polycrystals. If there is a certain grain orientation, then the polycrystal is textured and has anisotropy.

slide 14

Edge dislocation exit to the boundary Screw dislocation of crystal growth. Accumulation of dislocations at grain boundaries Dislocation network Screw dislocation 5. Dislocations are a nonequilibrium type of defect, i. their appearance is due to the prehistory of the sample and is associated either with the growth of a crystallite, or with the action of external loads or influences. There are several types of dislocations: edge, screw, mixed. Their accumulations often form grain boundaries.

Edge dislocation exit to the boundary Screw dislocation of crystal growth. Accumulation of dislocations at grain boundaries Dislocation network Screw dislocation 5. Dislocations are a nonequilibrium type of defect, i. their appearance is due to the prehistory of the sample and is associated either with the growth of a crystallite, or with the action of external loads or influences. There are several types of dislocations: edge, screw, mixed. Their accumulations often form grain boundaries.

slide 15

Depending on the dimension, the following types of defects are distinguished: 1. Point defects: Interstitial atoms and vacancies, Impurity atoms 2. Linear defects: Dislocations 3. Flat defects: Crystal boundary, Polycrystals Phenomenological characteristics of point defects: - formation energy; - energy of migration; - expansion volume.

Depending on the dimension, the following types of defects are distinguished: 1. Point defects: Interstitial atoms and vacancies, Impurity atoms 2. Linear defects: Dislocations 3. Flat defects: Crystal boundary, Polycrystals Phenomenological characteristics of point defects: - formation energy; - energy of migration; - expansion volume.

slide 16

In an ideal structure of any type, an atom occupies a position corresponding to a lattice site. An extra atom, for which there is no corresponding site, occupies an interstitial position. There may be several such provisions for a structure. Different types of interstitial carbon atoms in the diamond lattice: a - Tetrahedral - T; b – Hexagonal –H; (c) internode in the middle of the connection – M; d - Split internode (dumbbell -). internode

In an ideal structure of any type, an atom occupies a position corresponding to a lattice site. An extra atom, for which there is no corresponding site, occupies an interstitial position. There may be several such provisions for a structure. Different types of interstitial carbon atoms in the diamond lattice: a - Tetrahedral - T; b – Hexagonal –H; (c) internode in the middle of the connection – M; d - Split internode (dumbbell -). internode

slide 17

An extra atom, for which there is no corresponding site, occupies an interstitial position and perturbs the electron density distribution inside the unit cell. The level of the depicted isosurfaces is the same = 1.25

An extra atom, for which there is no corresponding site, occupies an interstitial position and perturbs the electron density distribution inside the unit cell. The level of the depicted isosurfaces is the same = 1.25

slide 18

Vacancies in covalent compounds The absence of an atom in a lattice site creates a point defect of the vacancy type: Vacancy and divacancy configuration in diamond The pattern of displacements differs from the displacements for interstitial atoms in direction, usually the nearest environment is shifted to an empty site. In connections ion type vacancies are formed in pairs, which is an energetically more favorable configuration for a given structure (Schottky defect). There is a need for neutrality. This type of defects manifest themselves more favorably, the higher the ionicity of the bond, for example, in NaCl. We also note that in the HTSC of the YBa2Cu3O7 type, the bond is observed partially as an ionic bond.

Vacancies in covalent compounds The absence of an atom in a lattice site creates a point defect of the vacancy type: Vacancy and divacancy configuration in diamond The pattern of displacements differs from the displacements for interstitial atoms in direction, usually the nearest environment is shifted to an empty site. In connections ion type vacancies are formed in pairs, which is an energetically more favorable configuration for a given structure (Schottky defect). There is a need for neutrality. This type of defects manifest themselves more favorably, the higher the ionicity of the bond, for example, in NaCl. We also note that in the HTSC of the YBa2Cu3O7 type, the bond is observed partially as an ionic bond.

slide 19

There is no atom in the corresponding site, which leads to a perturbation of the electron density distribution inside the unit cell Single vacancy in diamond The distribution of electron density in an ideal diamond unit cell and in a cell containing a single vacancy. The level of the depicted isosurfaces is the same = 1.25

There is no atom in the corresponding site, which leads to a perturbation of the electron density distribution inside the unit cell Single vacancy in diamond The distribution of electron density in an ideal diamond unit cell and in a cell containing a single vacancy. The level of the depicted isosurfaces is the same = 1.25

slide 20

slide 21

Model of Vacancy Formation in Simple Substances The following mechanism of vacancy formation can be proposed. The atom is carried to the crystal boundary, while the number of particles in the system does not change. Indeed, a simple removal of an atom from a crystal lattice site to infinity changes the number of particles in the system, and this fact must be taken into account to calculate the thermodynamic potential of the system. In the vicinity of the formed vacancy, relaxation of atoms will occur (red arrows in the figure). We will assume that two atoms of a substance interact with each other through a pair interaction potential, which does not depend on the environment of the atoms.

Model of Vacancy Formation in Simple Substances The following mechanism of vacancy formation can be proposed. The atom is carried to the crystal boundary, while the number of particles in the system does not change. Indeed, a simple removal of an atom from a crystal lattice site to infinity changes the number of particles in the system, and this fact must be taken into account to calculate the thermodynamic potential of the system. In the vicinity of the formed vacancy, relaxation of atoms will occur (red arrows in the figure). We will assume that two atoms of a substance interact with each other through a pair interaction potential, which does not depend on the environment of the atoms.

slide 22

The energy of an atom located at the site of the crystal is equal to Esite = z1*φ(R*), where the number of nearest neighbors is of the order of z1 6 - 8, R* is the equilibrium interatomic distance, the estimate of the potential φ(R*) can be made, for example, from sublimation energy of the substance, which gives φ(R*) ≈ 0.2 ÷ 0.3 eV. Thus, the value of the energy of an atom at a lattice site is equal to Esite ~ 1.6 ÷ 2.4 eV. Such energy must be expended on breaking bonds during the formation of a vacancy. However, the removed atom is placed on the surface; therefore, we can assume that half of the broken bonds are restored. The energy of an atom on the surface is Thus, the energy of vacancy formation is Ef ≈ 0.8–1.2 eV. Migration of vacancies Consider the migration of vacancies. In order for atom A to jump to the empty site where the vacancy is located, it would seem that it does not need to overcome the barrier, but this is not so - it is necessary to break the bonds. Calculation of the energy of vacancy formation

The energy of an atom located at the site of the crystal is equal to Esite = z1*φ(R*), where the number of nearest neighbors is of the order of z1 6 - 8, R* is the equilibrium interatomic distance, the estimate of the potential φ(R*) can be made, for example, from sublimation energy of the substance, which gives φ(R*) ≈ 0.2 ÷ 0.3 eV. Thus, the value of the energy of an atom at a lattice site is equal to Esite ~ 1.6 ÷ 2.4 eV. Such energy must be expended on breaking bonds during the formation of a vacancy. However, the removed atom is placed on the surface; therefore, we can assume that half of the broken bonds are restored. The energy of an atom on the surface is Thus, the energy of vacancy formation is Ef ≈ 0.8–1.2 eV. Migration of vacancies Consider the migration of vacancies. In order for atom A to jump to the empty site where the vacancy is located, it would seem that it does not need to overcome the barrier, but this is not so - it is necessary to break the bonds. Calculation of the energy of vacancy formation

slide 23

In addition, along the migration path of a vacancy (or atom A), an energy barrier (energy lens) appears, created by the nearest atoms. This is most clearly seen in a three-dimensional crystal. The number of nearest neighbors in the ABCD cross section is usually less than at the site, z2 = 4. If we assume that the pair potential changes weakly, then the energy barrier for vacancy migration can be estimated as Emγ ≈ 0.8–1 eV.

In addition, along the migration path of a vacancy (or atom A), an energy barrier (energy lens) appears, created by the nearest atoms. This is most clearly seen in a three-dimensional crystal. The number of nearest neighbors in the ABCD cross section is usually less than at the site, z2 = 4. If we assume that the pair potential changes weakly, then the energy barrier for vacancy migration can be estimated as Emγ ≈ 0.8–1 eV.

slide 24

Dilational Vacancy Volume Let ω0 be the volume per atom of the solid. When a vacancy is formed, the surface will be distorted due to relaxation, and the crystal volume V will change. Estimates give approximately δV(1)= - 0.1ω0, this result was obtained on the basis of the results of dilation experiments associated with the introduction of many vacancies into the sample. Note that in the matrix surrounding the area of vacancy formation, some increase in the substance density occurs due to relaxation. In the mechanism of vacancy formation discussed above, the atom comes to the surface. The associated additional volume change is δV(2)=+ω0. Thus, the total change in the volume of the crystal is: δV=δV(1) + δV(2) =+0.9ω0 Change in volume

Dilational Vacancy Volume Let ω0 be the volume per atom of the solid. When a vacancy is formed, the surface will be distorted due to relaxation, and the crystal volume V will change. Estimates give approximately δV(1)= - 0.1ω0, this result was obtained on the basis of the results of dilation experiments associated with the introduction of many vacancies into the sample. Note that in the matrix surrounding the area of vacancy formation, some increase in the substance density occurs due to relaxation. In the mechanism of vacancy formation discussed above, the atom comes to the surface. The associated additional volume change is δV(2)=+ω0. Thus, the total change in the volume of the crystal is: δV=δV(1) + δV(2) =+0.9ω0 Change in volume